Videogrammetry: revolution in construction site surveys

Norway-based Isachsen, a subsidiary of BetonmastHæhre, is a leader in technology-enabled construction, relying extensively on technology from drones to GPS-enabled equipment to improve efficiency, productivity, and communication. So, when the firm’s leaders recognized inefficiency in their survey-driven project tracking and quality check practice — of course they looked to technology for help.

Headquartered in Norway, Isachsen specializes in the construction of roads, tunnels, and railways, usually working on multiple projects at the same time. Using drones, Pix4D’s drone mapping software and a smart combination of desktop and cloud processing, the construction company Isachsen routinely monitors projects, keeps track of and document changes and easily communicates the site status to all stakeholders, including their end-client. |

The need for comprehensive reports to keep projects on schedule, on design, and on payment

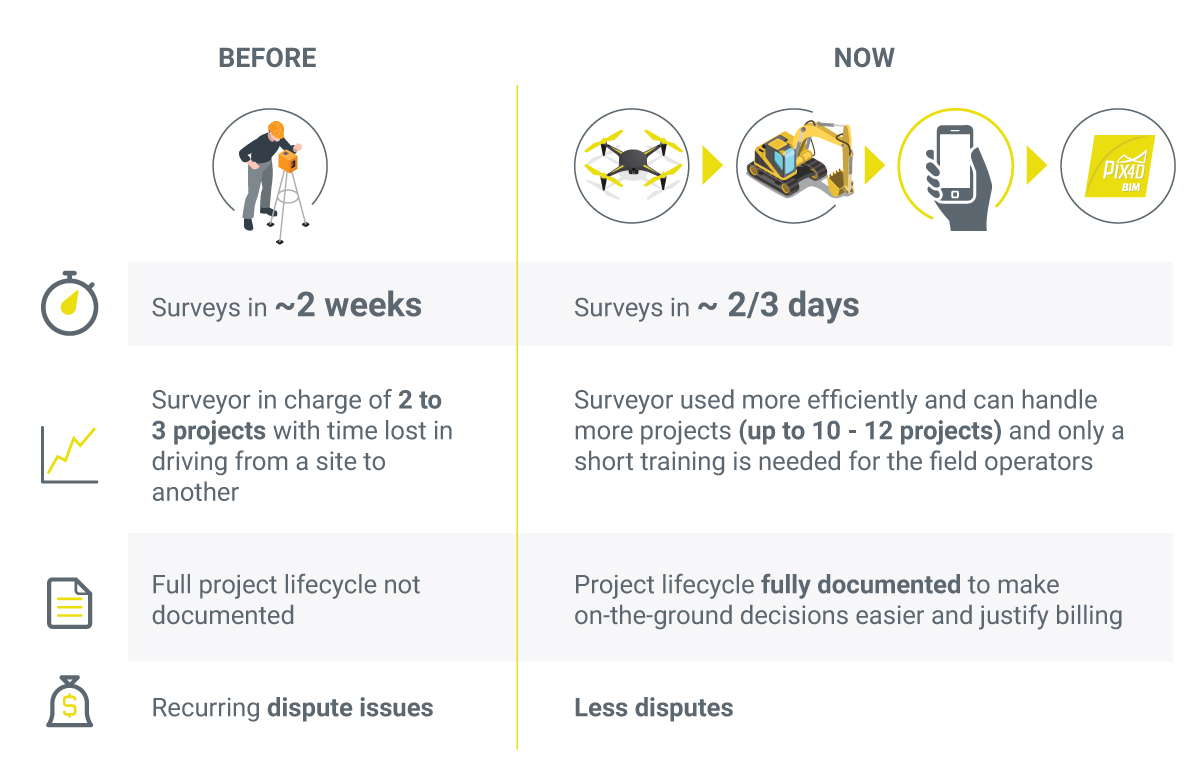

Problems arose when the firm’s expert team of surveyors was stretched thin driving from project to project verifying actual work and matching design specifications, particularly on excavation and sitework projects. Their measurements and subsequent reports are vital to maintaining project schedule and budget, receiving payment for all work that has been completed. Additionally, these reports are instrumental for communicating with clients about progress and eventually, serving as proof in disputes.

Trygve Almquist, Isachsen’s drone operator and surveyor, said, “From start to finish, our sitework teams look to our surveyors to verify that a site has been excavated, leveled or filled to specified dimensions. We needed a better process to visualize, measure and verify as-built data ease surveyor stress and improve efficiency.”About six months ago, Isachsen found the answer with a phone-based site survey approach based on Pix4Dmapper photogrammetry software. This approach empowers field operators to easily generate survey data with a smartphone and to continue operations without waiting for a surveyor to come on site and report on the project progress.

Video surveys: a smart and cost-effective workflow to get survey-grade data in minutes

The phone-based site survey approach using videos is straightforward, quick, and accurate.

As tasks are completed (like digging a hole or laying pipe), the construction crew paints 4-5 red marks around the completed area that needs to be measured for documentation purposes.Then, the equipment operator measures each one of the marks using the GPS in the excavator. Those measured marks are then used as ground control points. And because all the machines are remotely connected, the chief surveyor can directly access and collect the measurements from his office.

Isachsen surveyors say the video processing time is very fast since the frames are relatively small files. Better yet, the smartphone approach works in every weather condition, even night in artificial lights from the excavator.

Almquist adds, “It takes approximately two minutes for a technician to video the site and four minutes to measure the control points with the excavator’s GPS. Processing back in the office takes 12-15 minutes — certainly less time than it would take for the surveyor to drive to the project site. Better yet, once the video is complete, the construction crews can continue with their work, instead of pausing to wait for the surveyor to get to the site.”Almquist and the other surveyors especially like the ease of use of the data files. Every video file includes multiple pictures taken from many angles that can be measured and documented. He adds, “We can discover “forgotten” objects, which often leads to increased billing for work completed.”

Seamless practices

Since then, Isachsen has also incorporated the site survey process with video into its standard technology-enabled sitework practices. Typically, the Isachsen construction team flies one of its (25) DJI Phantom 4 drones over a work area throughout the course of a project (currently, they have 95 open construction sites).

Once gathered, the data is georeferenced and post-processed in Pix4D software to create a 3D topo plan for required work. That plan is sent via the cloud to the GPS-enabled excavator’s mapping system where the excavator can program the system to begin the next phase of work.

Now as tasks are complete, the technician performs the phone-based site survey as noted above. Once in the cloud, the surveyor pulls down and processes the data along with the marked GCPs. The final georeferenced product is a 3D model LiDAR-like point cloud (LAS file), which can then be sent to the construction site manager to verify that the as-built matches the as-planned specifications.Eliminate the chance of dispute

The drone, phone and Pix4Dcloud Advanced process works especially well for client communication, allowing the project team to keep the client current with very accurate project progress updates and eliminating the chance of dispute.

If any claim arises, the dispute can be settled by the timeline repository on the Pix4Dcloud Advanced platform that allows all project stakeholders to see exactly what was done the day of the claim or to track changes from day-to-day.

“Every task is documented and is easy to reconstruct. The frame extraction is brilliant, and it is a hidden gem which many overlook,” says Almquist. “We have been using this method [phone-based site survey] for about six months, and we see huge benefits from this on some of our sites. We have better control, more productivity, more documentation, fewer disputes—which all translates to time and cost savings.”