60% faster transmission tower inspections with drones

New technology and innovations in how infrastructure for industries is managed presents an exciting opportunity for companies. As regulations change and are updated, inspectors and asset management groups have the chance to bring new workflows to their projects to test the latest tools to make their work easier.

Inspecting transmission towers in Spain

In Spain, changing environmental regulations for transmission towers are requiring updates for how the powerlines are set up. All companies have 5 years to adapt their assets to be in line with the new rules that aim to reduce the risk of electrocution to birds that sit on the wires. The cables connected to the towers must be set up differently to have greater distance between lines and conductors. All towers need to be inspected, assessed, and potentially updated so that an accurate record can be used to confirm that the regulations are being followed.

CEGADRONE provides specialized asset management and inspection services, operating out of offices in Madrid and Segovia. They are experienced in inspecting assets like transmission towers, even at high altitudes that previously required helicopter inspections - now possible with drones. They are assisting clients in being compliant with the policy changes for more environmentally friendly practices for electrical and telecommunication assets. The UAV team at CEGADRONE is using PIX4Dinspect and PIX4Dscan to create intelligent digital twins integrated with AI that can be measured, annotated, and stored as a maintenance record. CEGADRONE has integrated PIX4Dinspect into their own platform so that they can take advantage of the 3D digital twin it provides.

Integrating PIX4Dinspect into their solution

PIX4Dinspect is a specialized inspection software that uses machine learning and artificial intelligence to optimize asset maintenance and records. When combined with the drone flight planning application PIX4Dscan, it provides a harmonious workflow that is entirely run on a cloud server, eliminating the need for clients to have powerful processing computers and instead taking advantage of being able to access records from anywhere in the world.

To demonstrate the product and workflow to clients, CEGADRONE has a practiced technique they showcase in webinars.

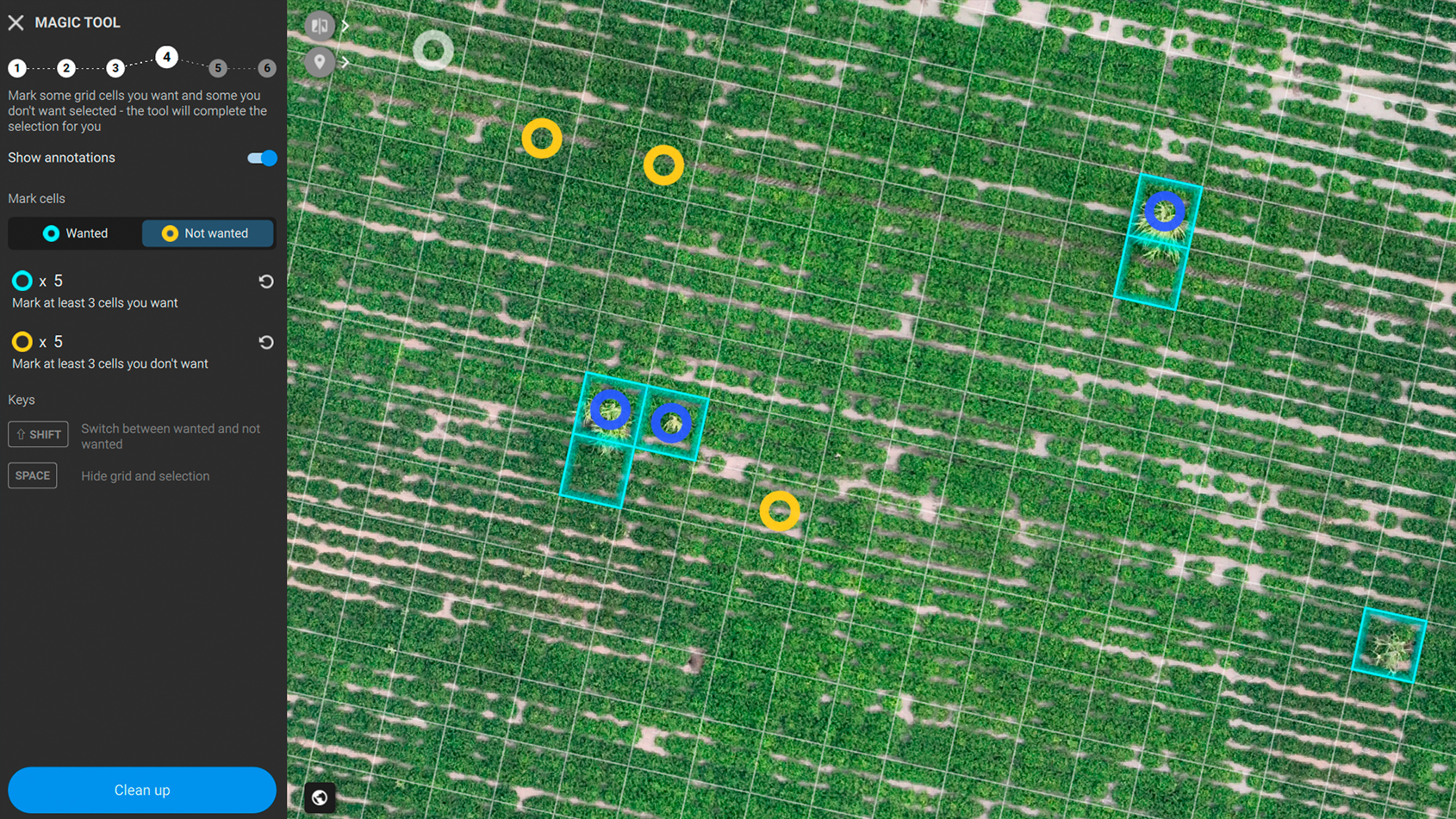

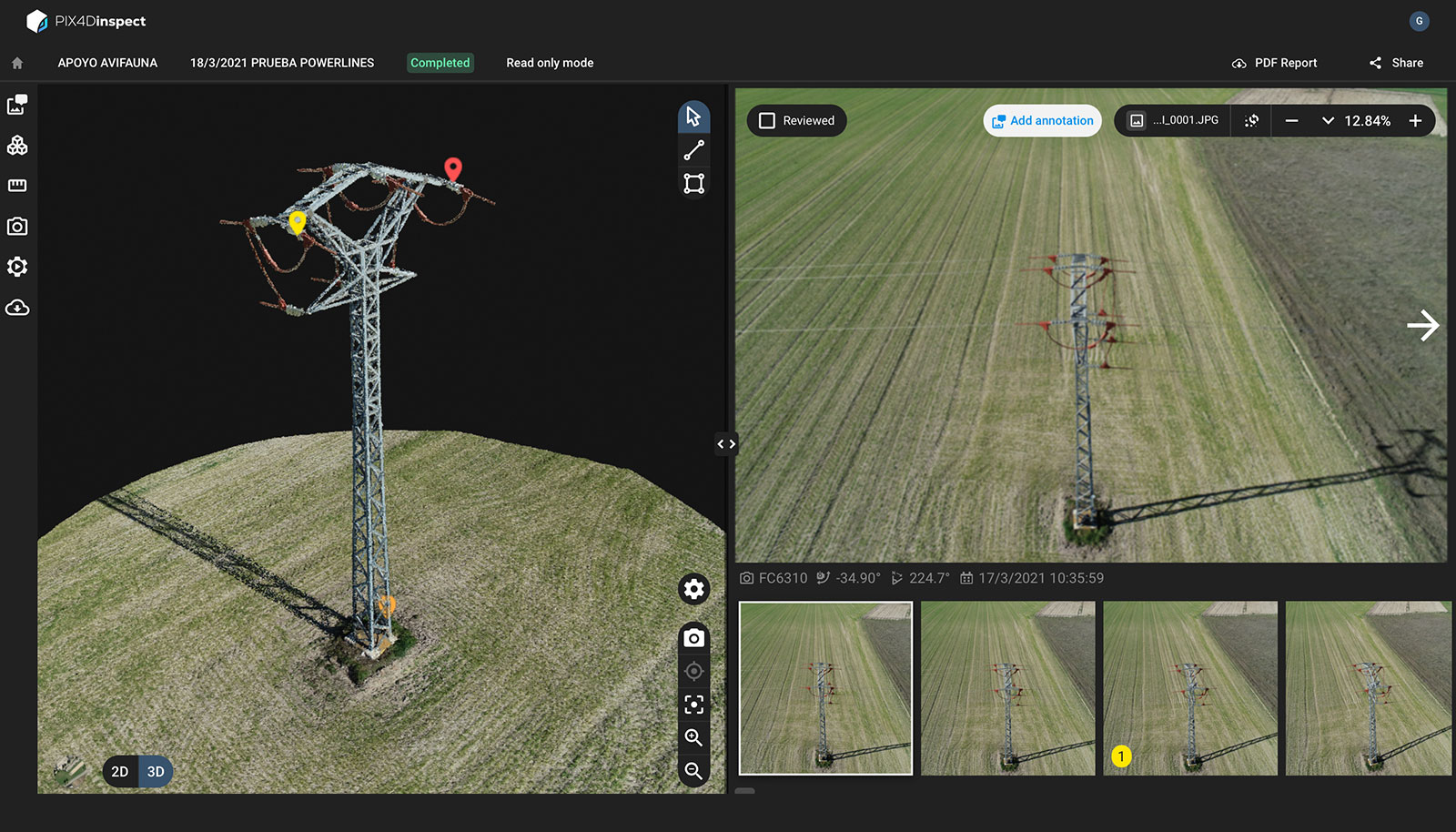

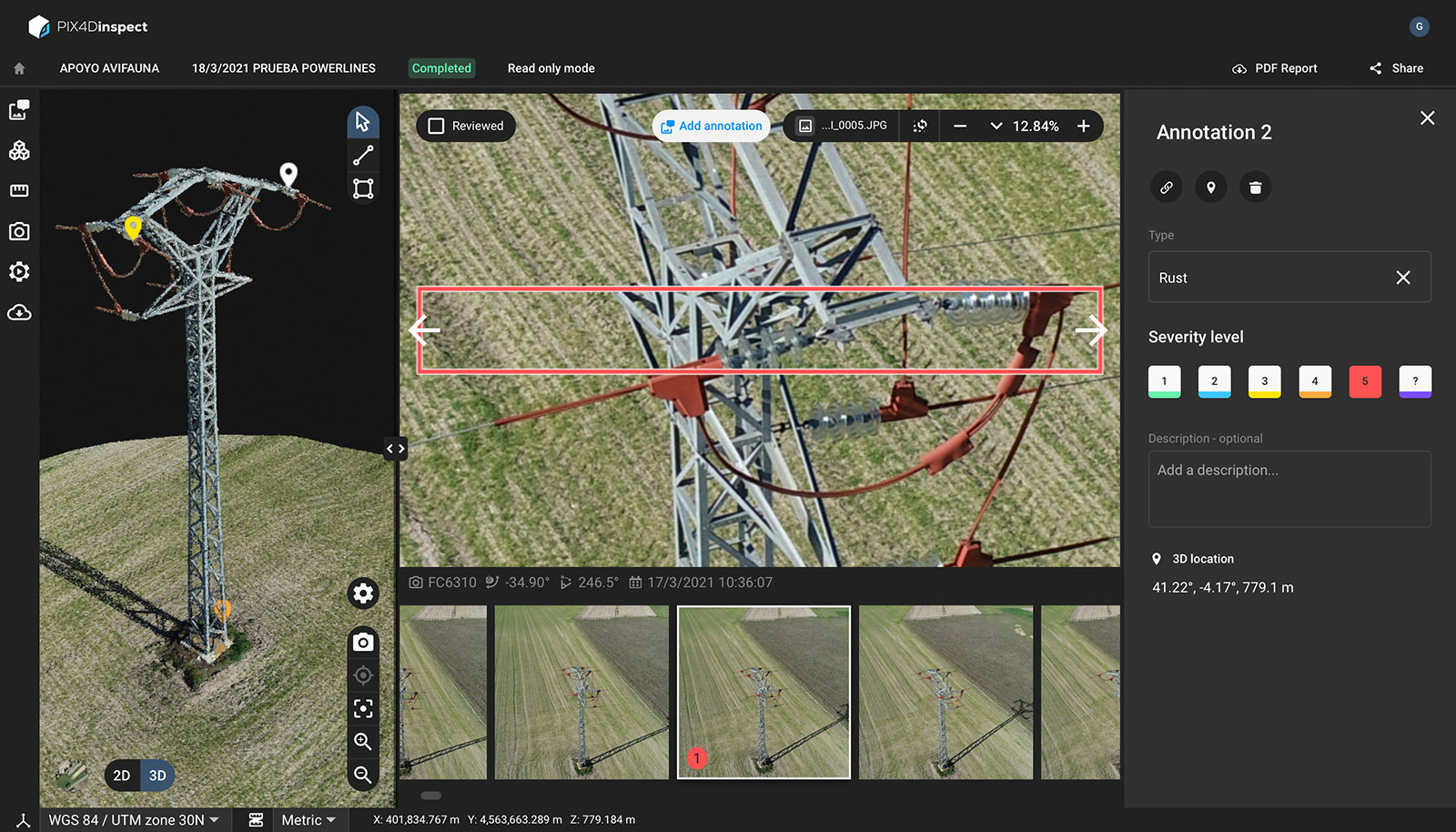

Firstly, they complete a demonstration flight or use a previously collected dataset. Next, the data is uploaded to the CEGADRONE platform, which can process a 2D result. Built into that UI is a link to PIX4Dinspect. With PIX4Dinspect, clients can examine their asset in 3D, including adding annotations, inspecting individual photos for each asset in 3D, and easily sharing the model along with a report. This is especially useful for power lines that are not easily visualized in 2D. Drone imagery, combined with PIX4Dscan and PIX4Dinspect,can accurately recreate power lines, which is vital for digital twins of transmission towers.

Projects details

| Company | CEGADRONE |

| Location | Spain |

| Software | PIX4Dscan PIX4Dinspect |

| Hardware | DJI Phantom 4 Pro DJI Matrice 300 RTK DJI Matrice 210 Parrot Anafi |

| Data capture duration per tower | 9 to 14 minutes |

| Tower height | From 12 to 65m |

Manual tower inspections vs drone inspections

A typical inspection workflow used to require an engineer to visit a site and climb the tower. They would then take photos, or draw diagrams, which would be transported back to the office and manually added to records. Manual measurements may also be taken by the tower engineer if they are able to easily access the targeted assets. It is a dangerous and slow process and reduces the number of towers visited in a day to a maximum of about 3, moving at a speed of about 4 kilometers per hour. Some sites required a helicopter due to the height of the tower, which is an expensive alternative.

The future of electrical inspections is faster. Using drones to inspect transmission towers and lines makes work 60% faster in CEGADRONEs' experience. They have worked with helicopters, but have found drones more effective as they are less affected by weather and specific flight permissions. CEGADRONE needs to provide inspections at least every 3 years so their clients have up-to-date records. Using drones is more cost effective than using helicopters, as well as being faster and safer. Time on site is also reduced to less than an hour.

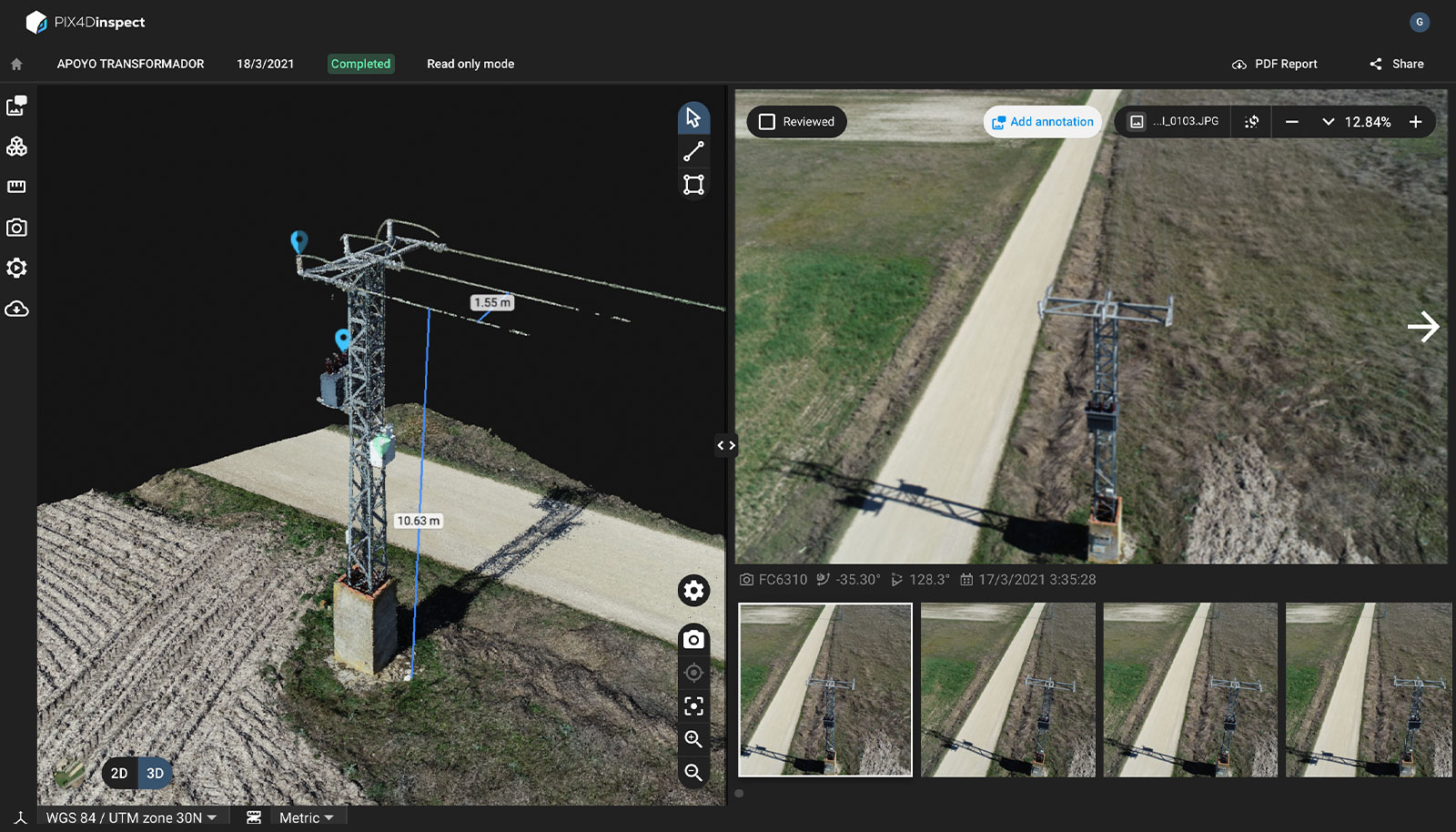

After collection, the photos are processed on the PIX4Dinspect platform while the team moves between sites, and results can be available as soon as 1h 25 minutes after upload.The “Master cameras” feature in PIX4Dinspect shows the minimum number of photos required to get an accurate digital twin. This has cut the number of photos from 90 to 18 which cuts the inspection time considerably. The future, says Miguel Ángel de Villota , is in 3D results: “We have to think in 3D, where we can take advantage of virtual reality. We used to have to do inspections over 6 months, and then provide reports manually over several months afterward. Now, we can have results in less than a day with a good connection.”

What is stopping drone inspections?

Like with any new practice, some users are nervous about integrating drones into their powerline or cell tower inspection workflow. An investment in UAVs and photogrammetry inspection software must be carefully considered. However, the proof of concept is already available all over the world.

CEGADRONE has internally proven a return on investment with cutting operational times to 60% of previous techniques. They are also working with software that can deliver results within an hour for telecom inspections, rather than a longer reporting turnaround that can be over 24 hours for a single tower. They have seen similar levels of success for transmission towers.

What enhances the value of working with drones to inspect transmission towers and electrical cables with drones is the scalability of the solution. Moving from tower to tower is much faster when processing can take place while teams are traveling between assets. In addition, because it is a cloud inspection platform, multiple transmission towers can be processed at the same time which makes the whole process even faster. They can then be analyzed using the PIX4Dinspect map of the assets across a region or country, which adds to the advantages of using drones for transmission inspections.

So while some inspectors are nervous about the transition to drones, the reality of using intelligent digital twins with integrated AI is clear to those already using it - and they are finding that it is giving them an edge over competitors.

Cutting-edge transmission inspection solution

The CEGADRONE team has been able to use automated, integrated AI to generate digital twins for clients that need accurate records to show compliance with national requirements and standards for transmission towers. The ability to “think in 3D” is setting them apart from other inspectors and providing a new, faster workflow. The greatest advantage has been the improved visualization of electrical wires and cabling, which can be measured on PIX4Dinspect. This empowers inspectors to determine if cables need to be adjusted in line with new regulations, or if the digital twin shows there is no necessary maintenance work. Each digital twin is then kept as a record to prove the company’s compliance with the environmental regulations.

As CEGADRONE measures tower cables and wires, they are able to help protect bird populations and prove just how accurate drone inspections for transmission towers can be. It’s an exciting step in a growing industry - where CEGADRONE is ahead of the curve thanks to PIX4Dinspect.