Mapping 300 acres at a former manufacturing facility

Old industrial sites are a challenge for modern communities. They can be a potential accident site, unattractive, and take up space. In some cases, disused factories or power plants are completely demolished. For this site in the Hudson Valley, New York, a private developer plans to expand the existing manufacturing facilities and add new facilities.

Originally opened in 1962, the site has a long history as a former computer chip manufacturing plant that was the backbone of the local economy. From the 1990s, the plant was slowly phased out of operation and the region was left with a largely empty manufacturing and office facility. Until recently, activity on the site was based around the existing buildings. However, new development is set to take place in between the buildings and in the large, abandoned parking lots throughout the site.

M.J. Engineering and Land Surveying, P.C. (MJ) was hired to provide base mapping, utility mapping, and topographic mapping for new warehouses and manufacturing facilities on the site. MJ is a specialized surveying company with experience in assessing large sites, infrastructures such as roads and bridges, as well as less urban areas for landscape architecture and land use planning.

Project details

| User | M.J. Engineering and Land Surveying (MJ) |

| Location | Hudson Valley, New York |

| Software | PIX4Dmatic PIX4Dsurvey |

| Hardware | WingtraOne |

| Area surveyed | 300 acres (121 hectares) |

| Total images collected | 2808 at 42 MP |

| Processing time | 4 hours |

| Processing hardware | Puget Systems computer, RAM: 128 GB, CPU: AMD Ryzen Threadripper with 32 cores, Storage: SSD drives |

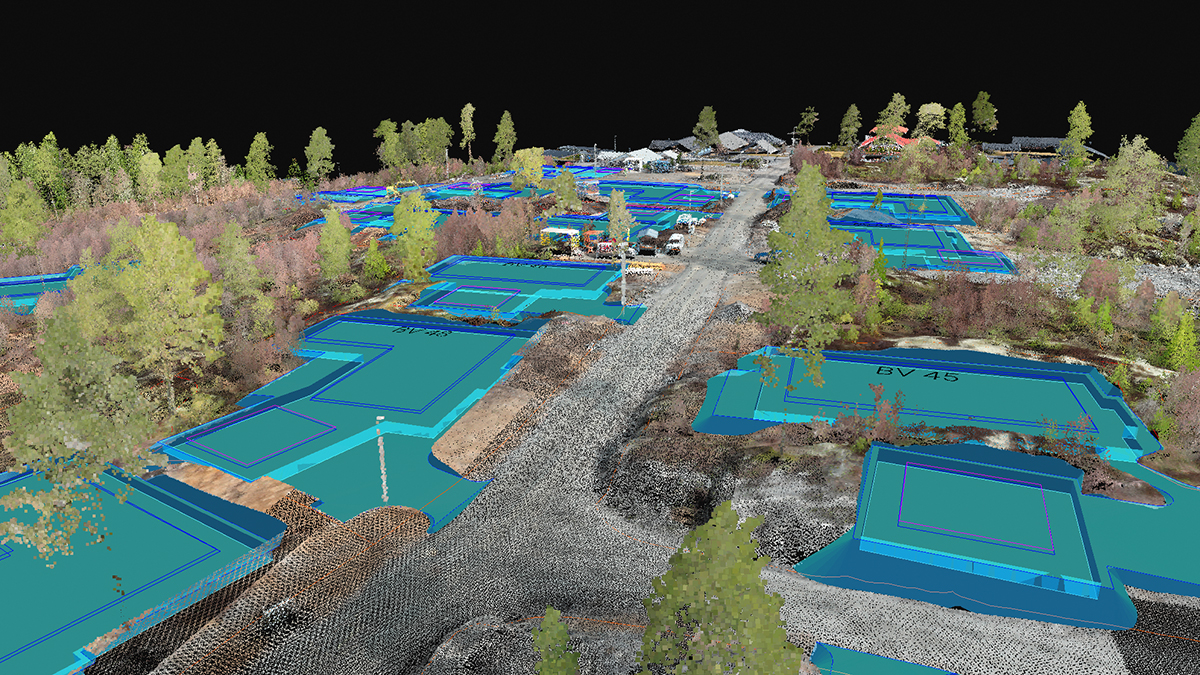

Utility mark outs and planimetrics

One of the key concerns for this project was the location of underground utilities. Over the past 60 years, the site has undergone numerous additions and modifications with little to no documentation of the utilities. MJ hired a sub-consultant to provide GPR (ground-penetrating radar) and utility mark out in the areas of the proposed development. Once complete, MJ utilized their WingtraOne UAS to capture 2808 images at 42MP that were processed in PIX4Dmatic into an orthomosaic with an average GSD of 0.044ftUS (1.34cm) over the entire site. By inserting this high-resolution orthomosaic into CAD, MJ was able to trace the utility mark outs and planimetric features significantly faster than traditional survey crews could locate them. Some traditional survey was still needed to collect manhole and storm inlet rim data and invert information.

Drone imagery acquisition

The site was mostly open, occupied by 1/3 buildings and 2/3 parking lots. There was no significant elevation change across the site. However, the site is surrounded by public highways on three sides and a high voltage electric transmission line on the fourth. There are tall smokestacks and a water tower on the site. Because a low GSD was needed for the imagery, the flight was conducted at 280ft AGL (85m). MJ used a small UAS to confirm that proper clearance would be kept over the transmission line and stacks. The flight was carefully planned as not to fly over occupied roadways and to minimize risk.

The total flight time was just over two hours, including battery changes. The pilot worked as fast as possible to avoid the collected imagery being affected by changing light conditions.

Topographic data meeting the 5cm ASPRS specifications

In addition to the utility survey, topographic information was also required. The project specifications required the data to meet the American Society for Photogrammetry and Remote Sensing (ASPRS) 10cm specifications. In the end, the data collected exceeded those requirements and met the 5cm ASPRS specifications. The PIX4Dmatic project used to create the orthomosaic contained the dense point cloud, which was imported to PIX4Dsurvey for topographic information to be extracted.

PIX4Dsurvey was used to extract ground points from the point cloud to create a TIN for use in CAD. MJ compared surfaces created with a standard point grid with the PIX4Dsurvey Smart Grid. The Smart Grid created a smaller and more manageable surface than the traditional grid surface with little noticeable variation in the quality. The surface was exported to AutoDesk Civil3D for final drafting.

Working with PIX4Dmatic and PIX4Dsurvey

Checkpoints and Ground Control Points (GCPs) were measured in the morning using RTN GPS connected to a NYSNET CORS Station. Measurements were taken with one minute observations utilizing survey grade receivers with GPS. The checkpoints and GCPS were re-measured in the afternoon connected to a different NYSNET CORS station as a check. The Wingtra used a local survey-grade GNSS base station. The GPS base station, CORS stations, and RTK observations were analyzed and adjusted in survey processing software which showed 2-4 hundredths vertical delta between the CORS stations. The team chose to hold the CORS station utilized in the morning observations based on their experience in the past with the station's vertical reliability.

A horizontal accuracy of 0.06ft (2cm) RMSE and a vertical accuracy of 0.12ft (4cm) RMSE were reached. The project was processed twice in PIX4Dmatic: once utilizing only the PPK results from the WingtraOne and the second time utilizing ground control points for comparison. The difference in results was less than 0.02ftUS (6mm horizontally and 0.013ftUS (4mm) vertically.

After the data was imported into PIX4Dmatic the calibration took 29 minutes, after which densification took 2 hours and 25 minutes. Additionally, the DSM took 18 minutes, while the orthomosaic took 2 hours and 3 minutes. The dataset was processed on a powerful computer, with 128 GB RAM, an AMD Ryzen 32 core Threadripper processor and high-speed SSD drives.

After the technical analysis and accuracy checks were done on PIX4Dmatic, the outputs were prepared for export to PIX4Dsurvey. Classifying the point cloud and extracting the TIN surface in PIX4Dsurvey was fast and produced excellent results for seamless use in CAD.

Part of the value of PIX4Dmatic and PIX4Dsurvey is the intuitive feel of the software. It is easy to use, provides GEOID support, and provides outputs that are easy for users to interact with, regardless of their size or the CAD software. With the ever-growing popularity of imagery and orthomosaics in the surveying industry, PIX4Dmatic and PIX4Dsurvey provide future-proof, relevant outputs.

Beyond the software: technical documentation and tutorials

MJ highlighted not only the ease of use of working with PIX4Dmatic and PIX4Dsurvey, but the heritage of it and other Pix4D products. The extensive and professional support available online, including the Pix4D Community, makes it easy for professionals to quickly get assistance if they need it.

“Pix4D has the best support out there. If there is a problem, Pix4D is on top of it. Many of us in the industry learned how to map with modern photogrammetry using Pix4D support articles and tutorials.” – Tom Cerchiara, PLS

The orthomosaic and other outputs from this project will be used to not only plan new developments but to compare to the site’s previous layouts, allowing planners to see how the site has changed over the years. The background map will be used for engineering work and gives a high-level overview of potential development and maintenance requirements. Despite the challenge of flying a highly detailed site, the MJ team provided actionable results for their clients.