Variable rate application with spraying drones

Trinoo is a precision agriculture company specializing in drone spraying for agriculture. It has been active since 2018, backed up by 2 years of research in the use of drones for spraying products in sugarcane cultivation. The company is located in the largest sugarcane production area in Colombia - the department of Valle del Cauca. This area has 14 sugarcane mills, where on average 240,000 hectares of sugarcane are harvested per year.

Reducing the sugarcane ripening agents and forecasting the crop production

One of the most important sugar mills in Colombia was looking to improve their efficiency in sugarcane ripening and to have a more accurate forecast of the production of tons of sugarcane per hectare of their fields. They decided to work together with Trinoo and in defining the scope of the project, the two companies established a research protocol that included:

- the technology to be used for image capture and subsequent processing

- the time when images should be taken according to crop development

- the sugarcane varieties to be analyzed, amongst other factors

The project’s goal was to reduce the use of ripening agents and improve the production of tons of sugarcane per hectare forecast. This would reduce production costs per hectare and improve the cash flow of the mill by providing more accurate field production forecasts up to 120 days before harvest.

Project details

| Location | Valle del Cauca, Colombia |

| Project duration | January - October, 2020 |

| Area covered | 600 hectares |

| Number of images | 30 000 |

| Software | PIX4Dfields |

| Hardware | Parrot Bluegrass drone for data capture DJI Agras MG-1P drone for spraying Parrot Sequoia camera |

| Image resolution | 8cm/pix-10cm/pix |

Applying the ripening agent with aerial spraying drones and variable rate maps

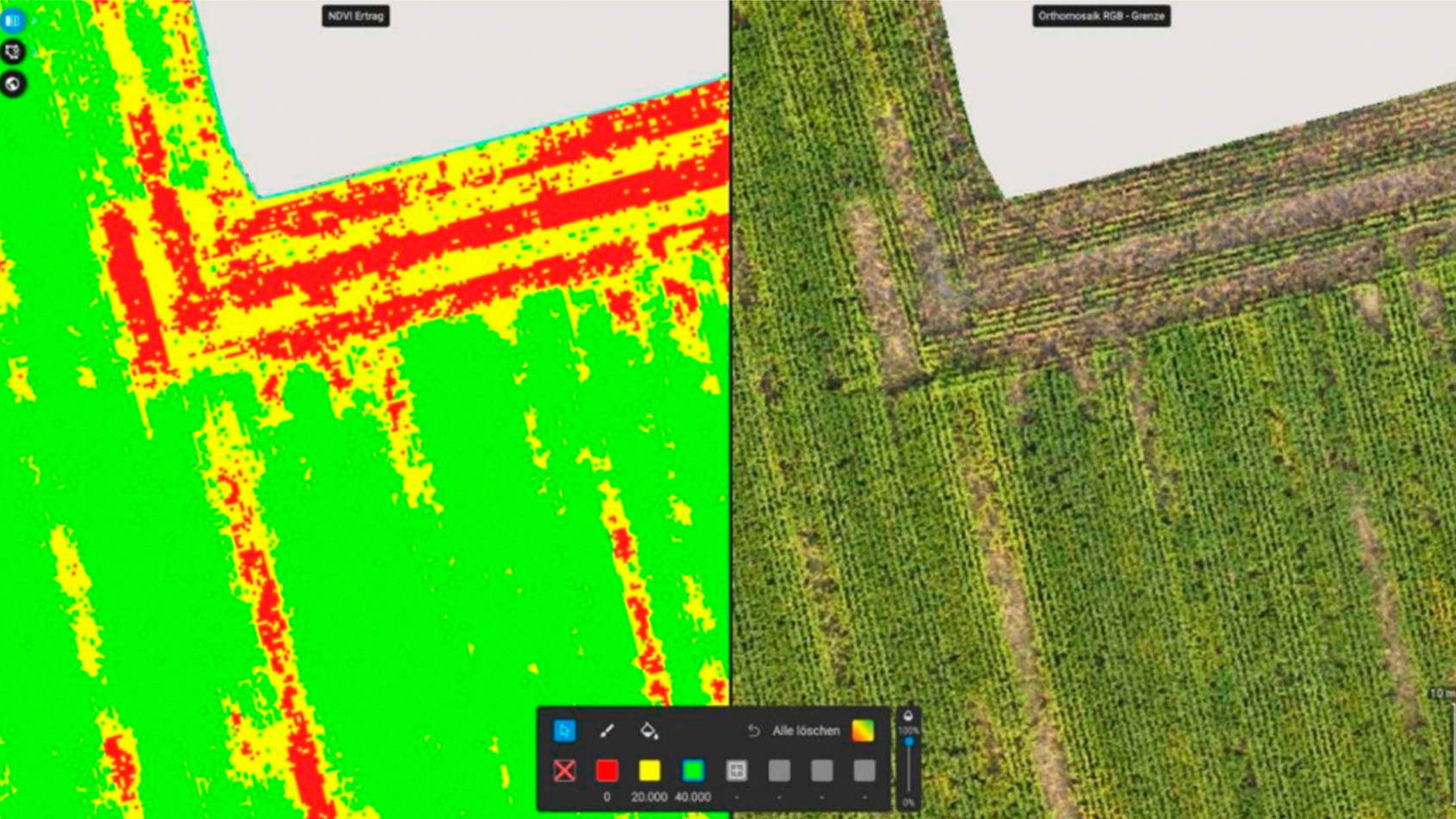

For the maturation process, a ripening agent is applied from the air on the crop leaves. It is induced to concentrate higher levels of sucrose in its stalk, which increases the sugar production per ton of sugarcane harvested per hectare. This work has traditionally been carried out with a uniform dose without taking into account that each lot, given the soil conditions, rainfall regime, and agronomic management presents different levels of development.

Additionally, the standard methodology used so far is the collection of samples in the field that are then analyzed in the laboratory, a process that generates variations due to the difficulty of having a truly representative sample of the entire lot.

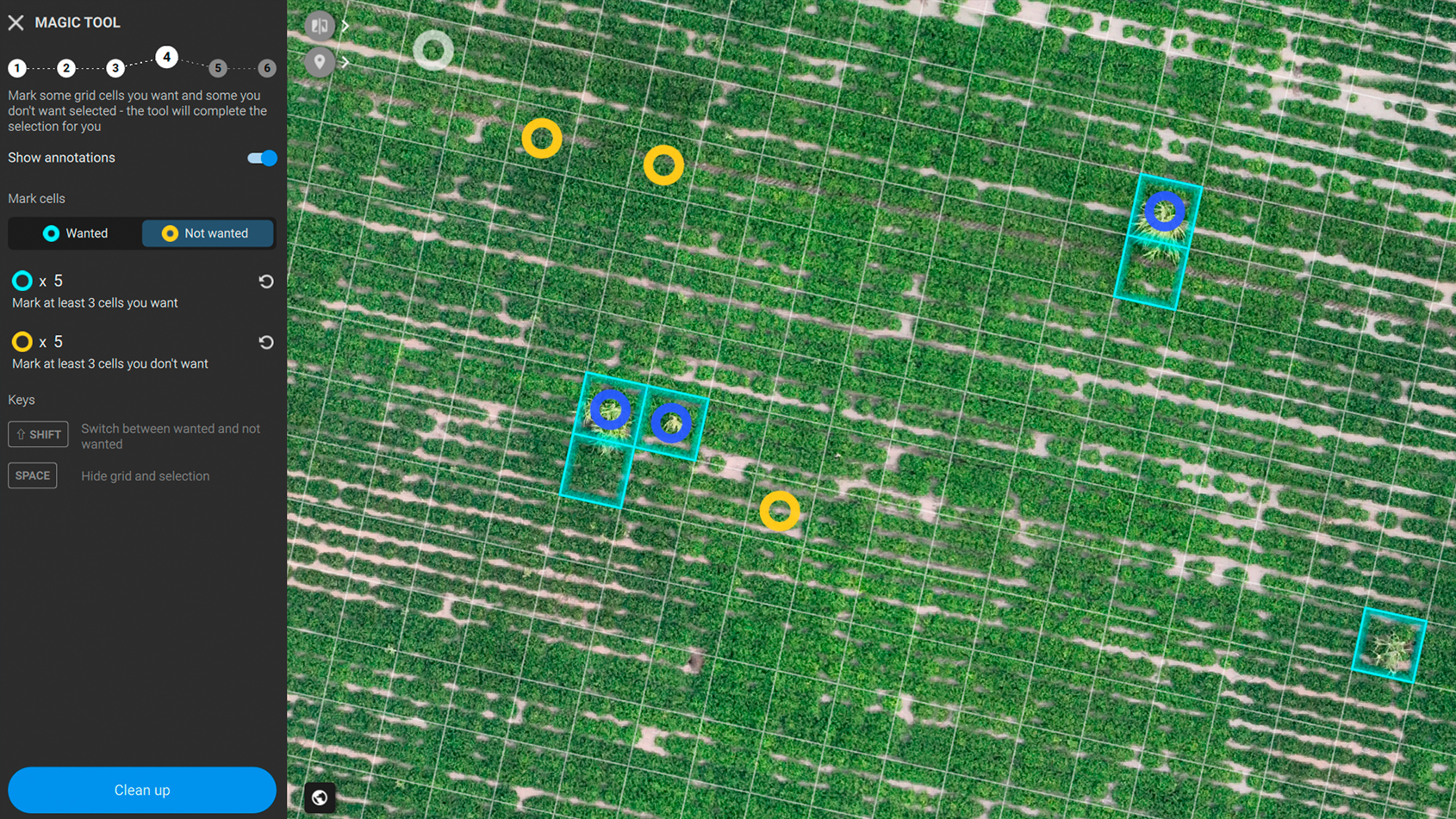

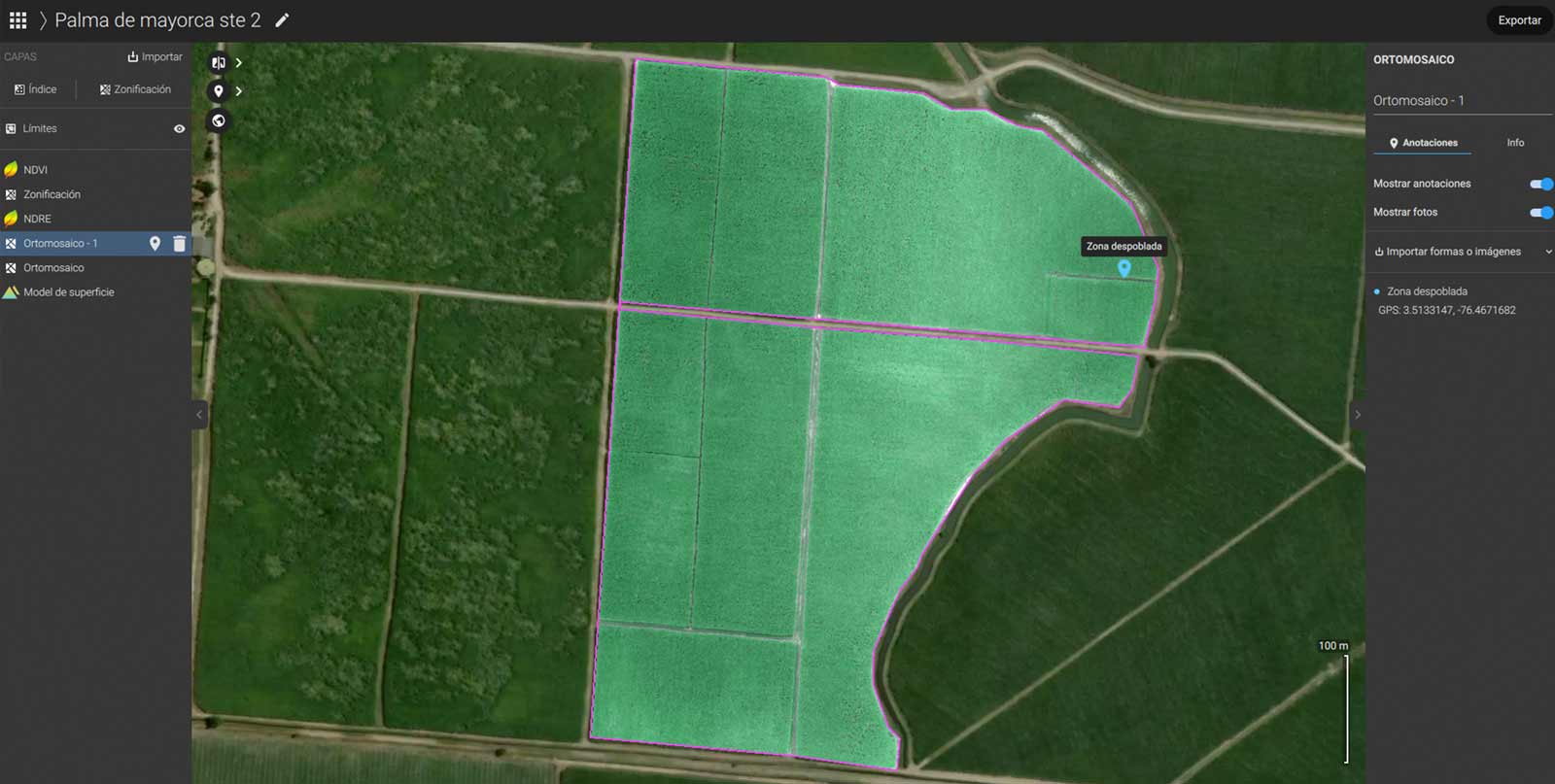

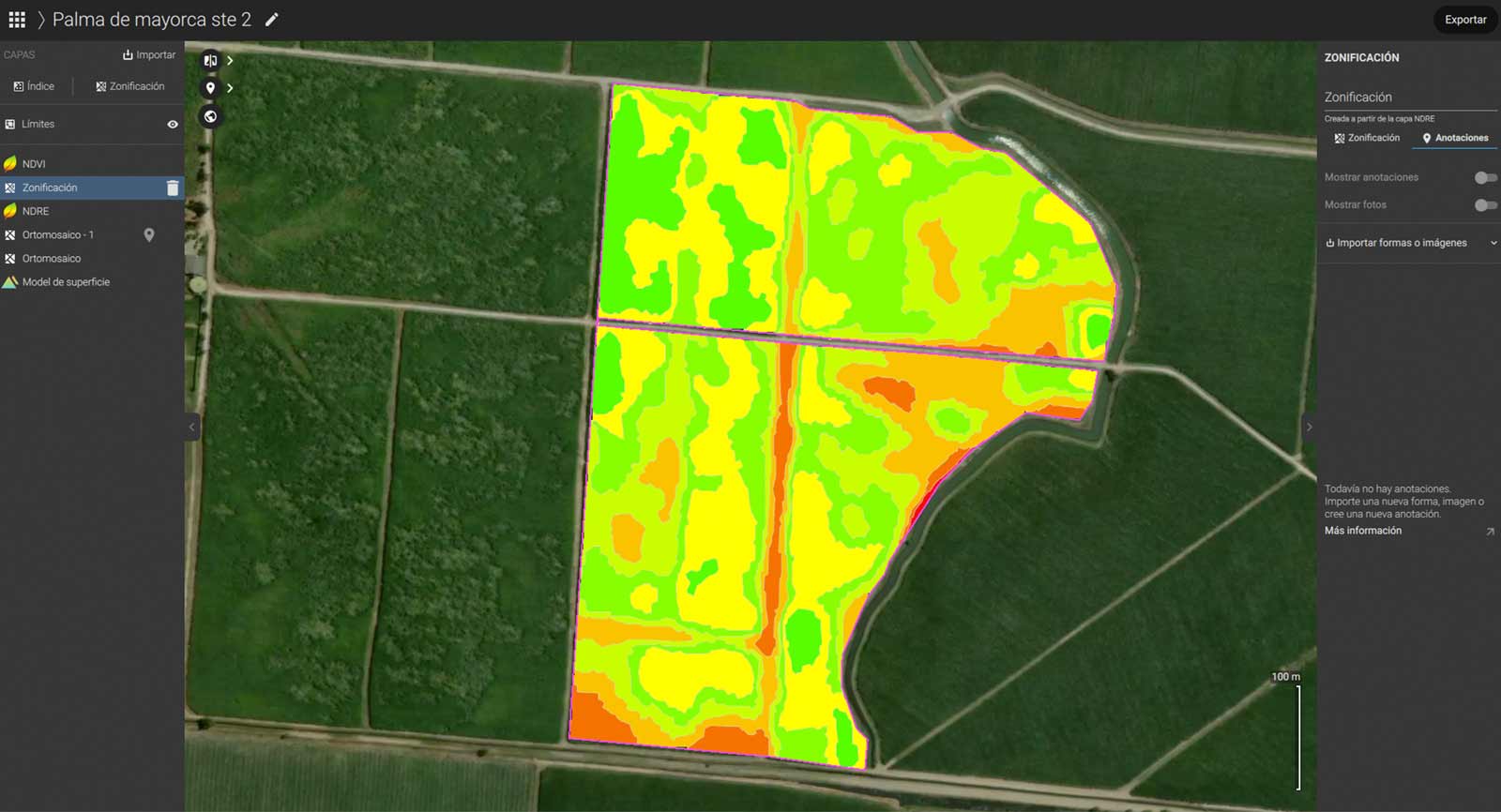

The maturation process, once combined with precision agriculture can be done with a variable rate, spraying more or less product with a spraying drone, according to the development stage of the crop. Trinoo proposed capturing images with a drone and spectral cameras, processing the images, and creating spraying drone variable rate maps in PIX4Dfields to apply the ripening agent.

Developing a sugarcane production forecasting algorithm

For this project, Trinoo developed an algorithm to calculate the tons of sugarcane per hectare from vegetation indices and other variables recommended by Trinoo's client's sugar mill harvesting team. In the field, the average size of the plots to be surveyed is 15 hectares, which generates challenges due to latency effects and disconnection of the drone in the farthest points from where the pilot was.

For the development of the forecasting algorithm, the starting point was the vegetation indices generated in PIX4Dfields. Then the patterning process had to be carried out, which is the identification of the spectral signature of each sugarcane variety and its relationship with the tons of sugarcane per hectare (biomass production), including variables such as age and variety of sugarcane being analyzed.

Project results

Reducing the ripening agent cost by 20%

By using precision agriculture methods and spraying drones, Trinoo's new service generated from this research project resulted in reducing the ripening agent purchase for sugarcane growers by 20%.

“That would mean for our customers - approximately USD 200,000 per year of savings. For the case of the entire sector made up of the 14 sugarcane mills located in Valle del Cauca, it could result in savings of USD 800,000 to USD one million per year”, points out Felipe Barney Arango, Innovation coordinator at Trinoo.

Achieving 93% accuracy rate in forecasting the sugarcane production

In the forecast of tons of cane per hectare, Trinoo achieved a 93% accuracy rate. “This information can improve the cash flow projection of the companies, the factory planning, and the sales projection of each sugar mill by being able to anticipate with up to 120 days the number of tons of sugarcane that will arrive from the field. This ultimately generates substantial savings in the planning of labor demand and amount of product to be marketed”, concludes Felipe.

Advantages of PIX4Dfields

For this research Trinoo processed 30000 images with PIX4Dfields, distributed in 26 projects. They found the following software advantages:

- High usability of the software with very intuitive functions that facilitate the work of the image processing technician.

- Low demand of computing capacity, allowing to run the software on a computer with only 4 GB RAM at an acceptable speed of image processing.

- Easy export of reports, results, images, and polygons, facilitating the integration of the work with other processes.

- The high variety of vegetative indices allowing multiple combinations of analysis.

- Compared to other software on the market that the Trinoo team had tried and based on the literature review, they found that PIX4Dfields showed a very good price-quality ratio and higher usability, for non-expert GIS researchers