Applying Pix in cotton with PIX4Dfields

What is Pix?

Most references to plant growth regulator (PGR) use in cotton involve mepiquat chloride (MC), a compound registered with the Environmental Protection Agency (EPA) in 1980 by BASF with the trade name Pix. Mepiquat and related products are almost exclusively the PGR used in cotton and, given its long history, Pix is the term routinely mentioned to discuss PGR applications in cotton1.Cotton is one of the most important crops grown in the United States and a staple of the fashion, personal care, and beauty industries, just to name a few. Once harvested, very little goes to waste, which makes cotton a very compelling and rewarding crop to grow.

Cotton has been cultivated for over 5,000 years and, only very recently, modern farming methods have replaced handpicking and horse plowing. Advanced machinery and other technological advancements like precision agriculture allow farmers to grow and harvest their crops more efficiently.

Growing cotton in Mississippi

Mast Farms LLC is a family-owned multi-generational farm that raises cotton in east Mississippi. Cotton plants tend to do well in deep, well-drained, and highly fertile sandy loam soils with a pH between 5.5 and 7.52. Most Mississippi row crop production (cotton, corn, and soybeans) occurs in the relatively flat, deep alluvial soils of the Delta that are conducive to mechanized farming3.

Technological advances in transgenic cotton varieties have allowed cotton to be managed and produced easier, and these advances continue to be significant reasons that yields have continued to increase4. Modifying cotton growth has become an essential component of cotton production as it can influence the yield if appropriately managed.

Plant growth regulators

The key to modifying growth is knowing what the plant needs at each stage of development to reach the final goal of higher yield and quality. The next step is to do everything possible to provide for these needs. Plant growth regulators can promote crop earliness, square and boll retention, higher nutrient uptake, and keeping vegetative and reproductive growth in harmony to improve lint yield and quality5.The number of synthetic plant growth regulators available to cotton growers is increasing. Pix has been the most widely used material due to its ability to reduce excessive cotton growth and emphasize boll development.

Quantix Mapper and PIX4Dfields

To know exactly when and where to apply Pix on their cotton fields, the Mast Farms team flies the AeroVironment Quantix Mapper drone to collect timely and accurate data. “It’s not any cheaper than using fixed-wing imagery but it gives us independence to get the job done in the fastest way possible,” says Lowell Mullet, Member Manager, Mast Farms LLC.

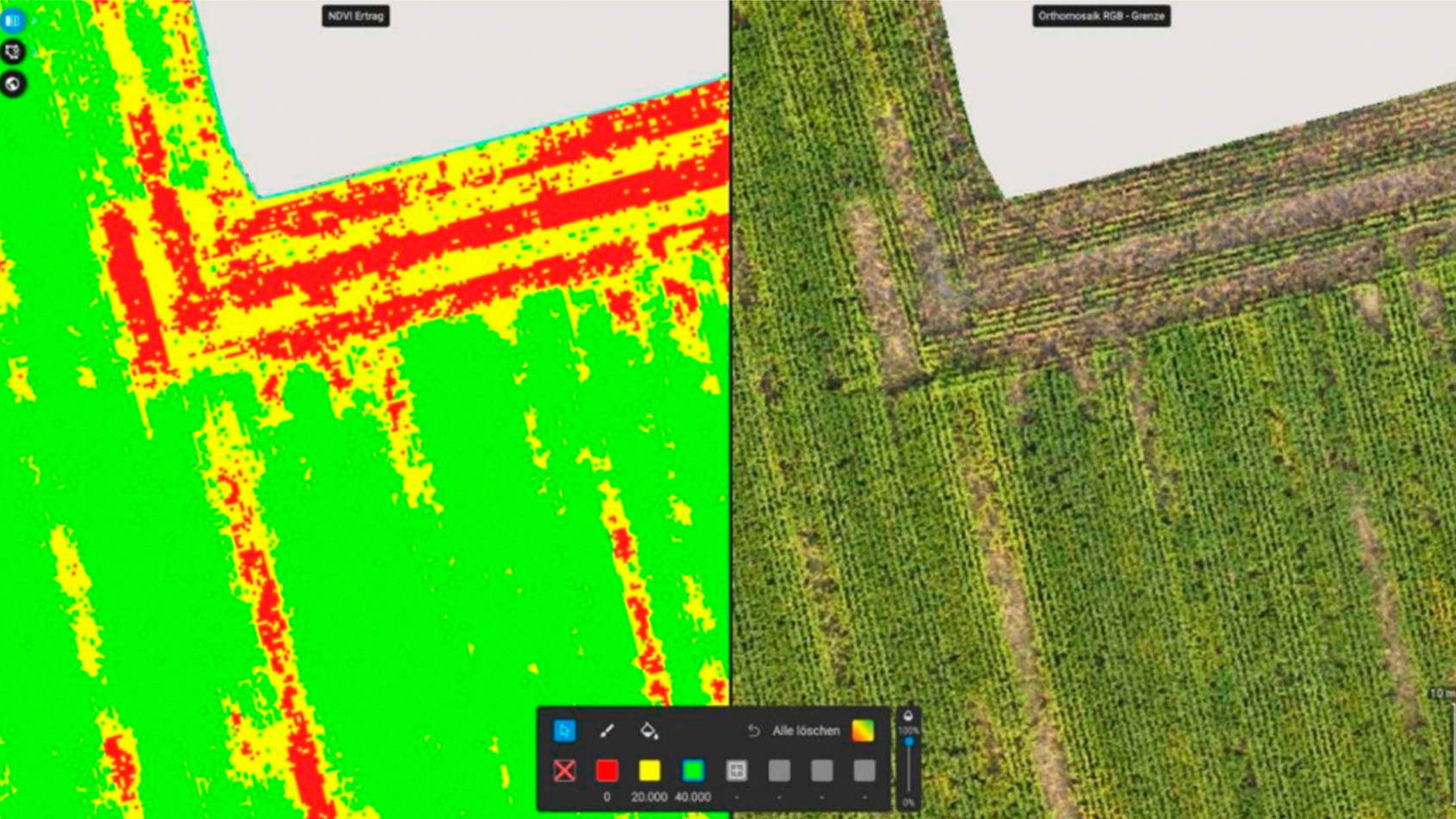

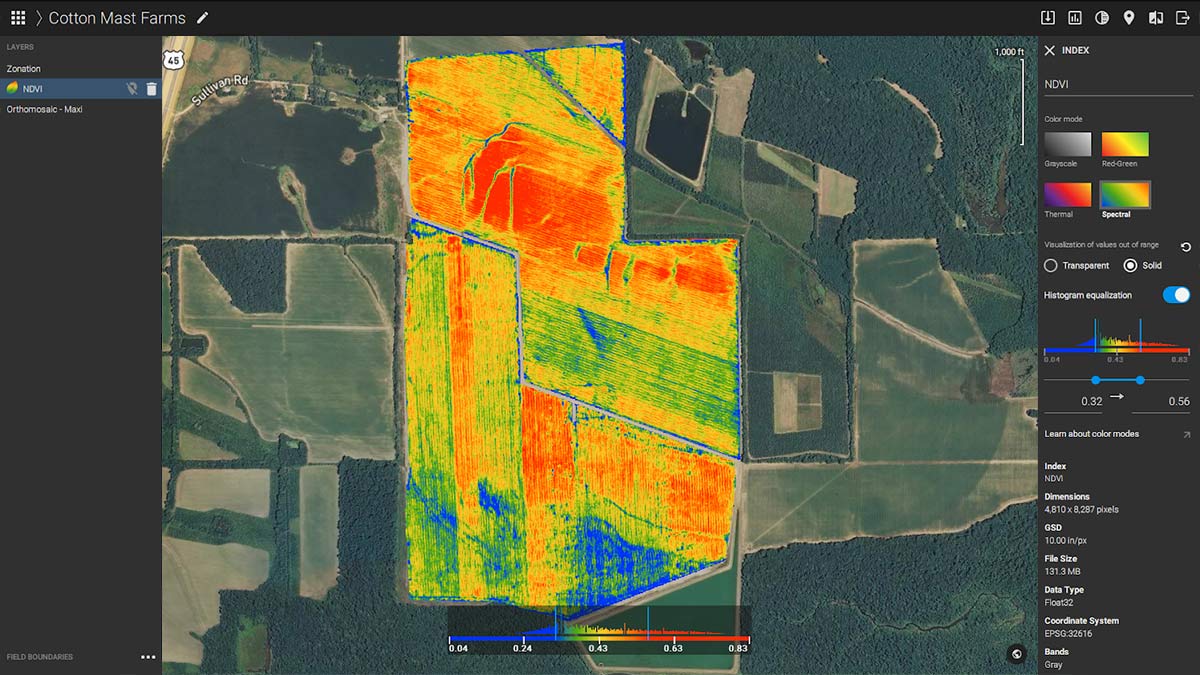

After capturing the images, the Mast Farms team processes them with PIX4Dfields to generate NDVI maps then create zonation maps.

“This particular field is 517 acres, and from the start of flying until I can have a prescription in sprayer is about two hours depending on pixel size when processing,” says Lowell. “I collected 20.4 Gb of data on the 517 acres and it took roughly 45 minutes to process it.”

More control over data

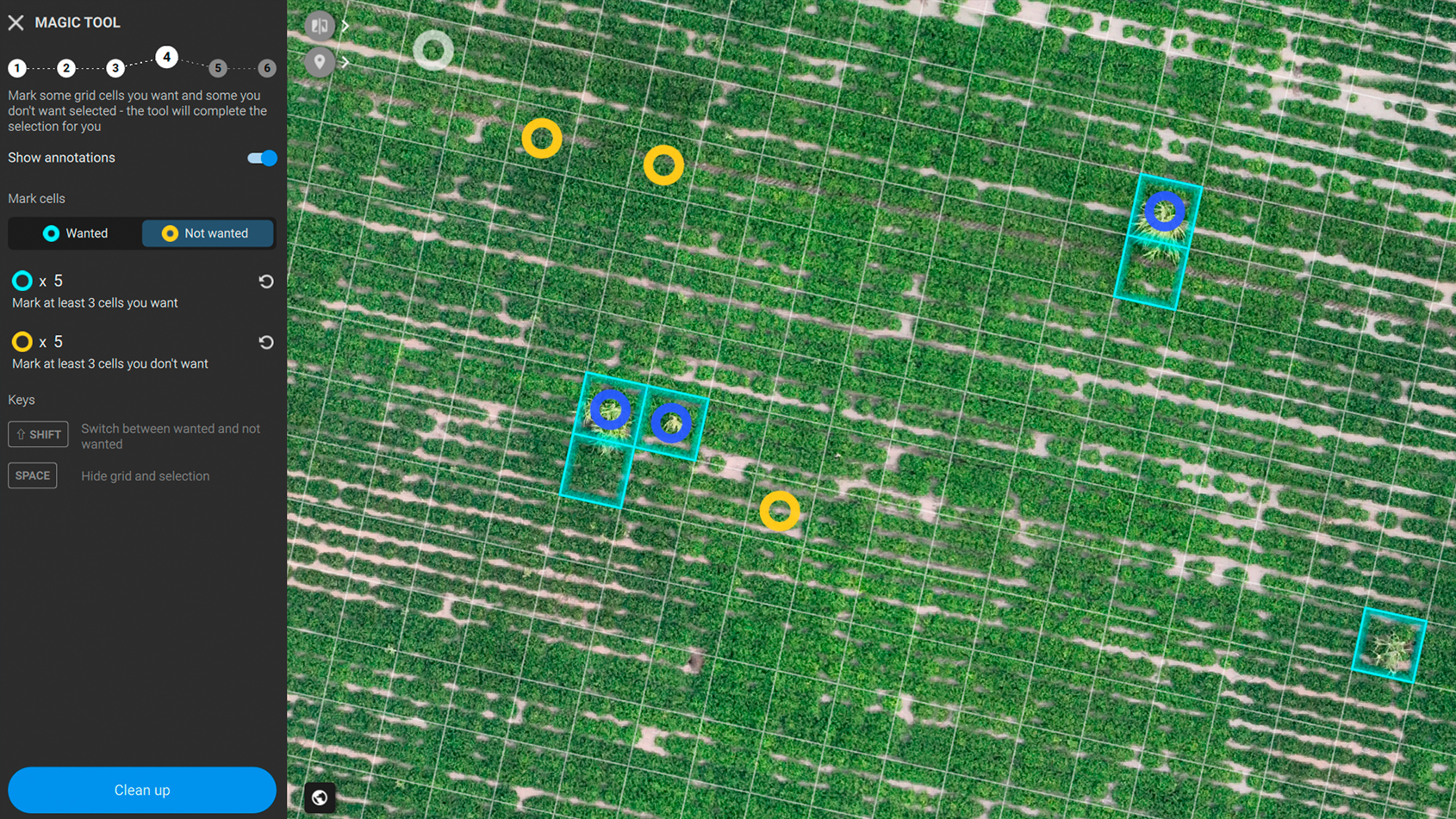

The most recent PIX4Dfields releases bring advanced layer visualization and enhanced GPU processing to help focus on the data that is important to you with greater speed. The added tools enable users to filter out roads, trees and fences and focus precisely on the crop.

Making a prescription for Pix

In many studies NDVI is found to be a consistent indicator of leaf area index and plant biomass. Because of this, NDVI or other indices can be ideal tools for classifying variability in plant growth across a field.

Using an NDVI generated in PIX4Dfields, Mast Farms was able to classify higher and lower areas of vegetation using the zonation tool in PIX4Dfields. The tool divided the field into three different levels of vegetation. The areas of the field were scouted to determine the height to node ratio (HNR). This is an important step in determining the rate of PGR to use for each zone.

Last, the zonation tool was used to create a prescription. Rates were assigned to each vegetation zone based on the HNR. The Haggie STS 16 was equipped with a Raven Sidekick so the Pix would be directly injected into the boom as they sprayed. Because of injection system rates of 8, 12 and 16 oz/acre were assigned per zone. To finish the prescription, the file was exported and loaded into the sprayer monitor for use.

Getting the job done

Mast Farms was able to quickly and efficiently apply Pix to their field of cotton using their Quantix Mapper, PIX4Dfields and STS 16 sprayer.

“The beauty of using the Quantix with PIX4Dfields is the timeliness of getting fields flown, processed, zoned, Rx (variable rate prescriptions) made and to the sprayer,” says Lowell. “PIX4Dfields has the ability to stitch the images, generate indices, create zones, and write prescriptions without having to use multiple programs and transferring data from one program to another. The program runs on a local PC so you can be flying crops and processing them out in the field on a laptop saving time.”

With no need for the internet or a beefy computer, the Mast Farms team was able to get the job done and move on to the next job.

Special thank you to Mast Farms for sharing their story with us.