PIX4Dcatch application: from field survey to as-built

CRAFTCOM Co., Ltd, an engineering consultant company for the Ministry of Land, Infrastructure, Transport and Tourism in Japan, have integrated the mobile 3D scanning app PIX4Dcatch, with an RTK device attached for accuracy, into their construction workflow. In this interview we explore the integration, application, and impact of this technology. Learn why CRAFTCOM embraced PIX4Dcatch.

Why did you introduce PIX4Dcatch into your workflow?

We decided to introduce PIX4Dcatch and mobile scanning into our workflow because of the highly accurate 3D models it produces and its ability to obtain precise location information. When we used another company’s solution for reproducing 3D images using smartphone LiDAR, we struggled to accurately reproduce the bridge abutment corners. In contrast, PIX4Dcatch combines three technologies: photogrammetry, RTK, and LiDAR, resulting in a remarkably clear reproduction of the bridge abutment corners, making it the more appealing option.

Could you share your experience using PIX4Dcatch for construction?

We used PIX4Dcatch in three main applications:

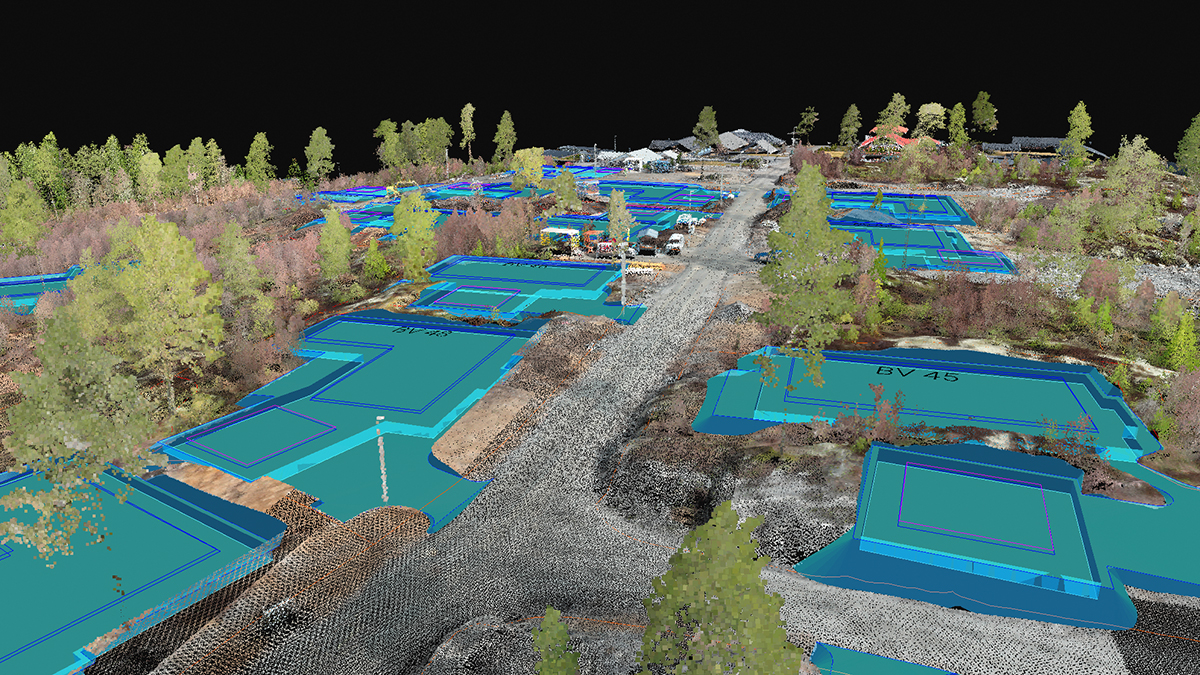

Site surveys: using a smartphone, we can easily generate a 3D model of the site, and then calculate the area and quantities of the site on the 3D model. This makes it easier to estimate construction costs and create construction plans, which has been useful on various sites, including concrete paving of gardens, reclamation of rice fields, and demolition of structures.

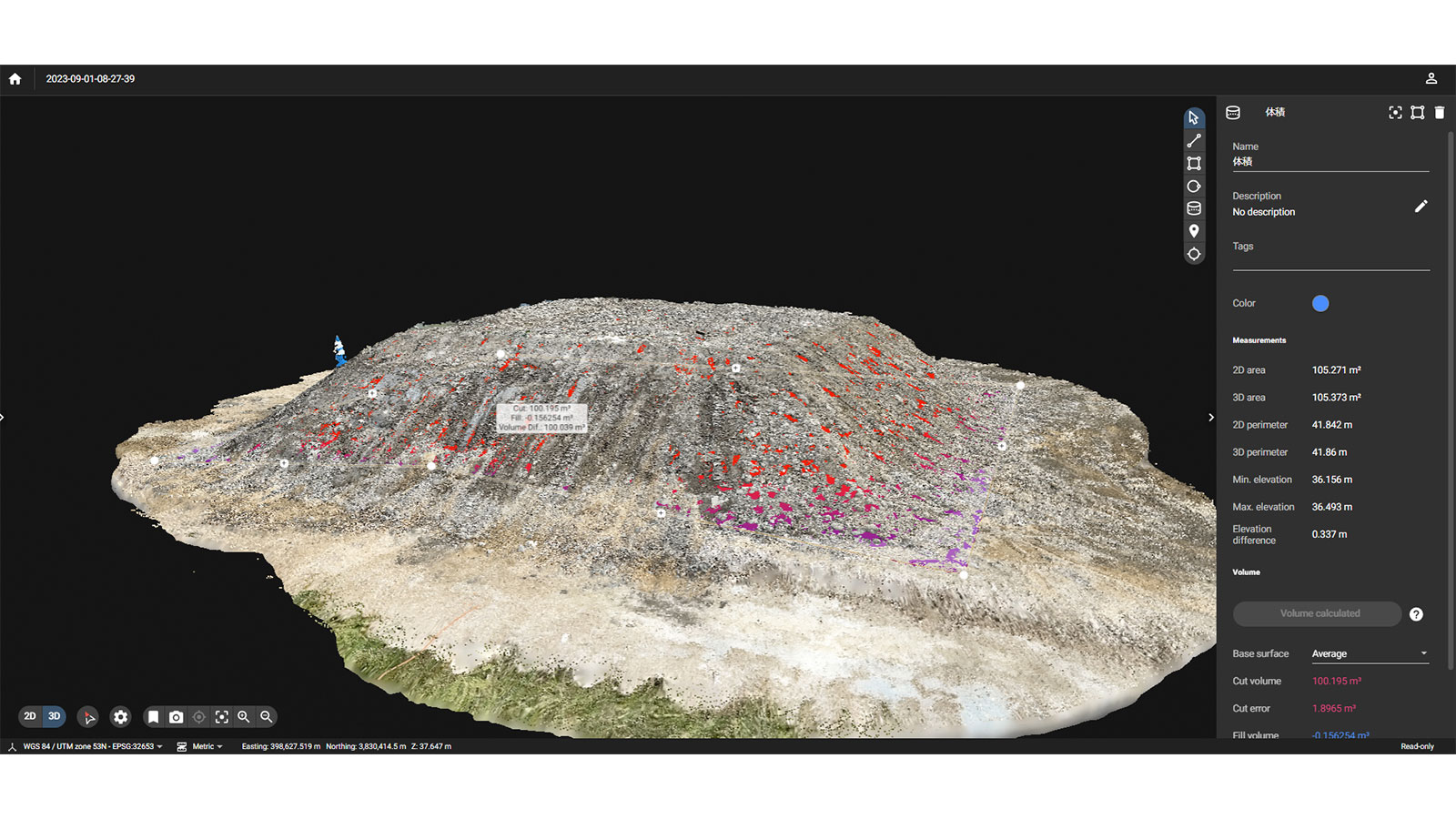

Soil volume measurement:soil volume measurement is frequently required, especially for public works projects. With PIX4Dcatch, data can be acquired simply by scanning a truckload of soil with a smartphone, which can then be modeled in three dimensions. The volume of the cut soil can then easily be measured and used for identification with stakeholders.

On-site use of structures: PIX4Dcatch is used to measure the geometry of structures such as piers in order to compare the design values with the actual structure. The dimensions of the structure can be measured in 3D to check for errors, compared to the design drawings. Currently, we are also comparing the results with those obtained using a laser scanner.

What results have you seen with PIX4Dcatch?

The introduction of PIX4Dcatch into our workflow has drastically changed our business processes. Because of its intuitive operation, we can now ask our clients to acquire and upload data themselves. Considering that before, two of our staff members would go to the site, take pictures, and make drawings in CAD in the office, it has made the process much more efficient. In addition, the use of a 3D model has made it easier to communicate the situation to the client visually and has facilitated the reporting process.

How do you plan to use PIX4Dcatch for future projects?

We plan to use PIX4Dcatch for the measurement of underground facilities such as lifelines and joint cable ditches. Specifically, we will use it to locate underground facilities and confirm that they are buried as designed. The results of the test excavation will also be recorded using a three-dimensional model instead of conventional photographs. We believe that PIX4Dcatch will be useful at underground burial sites because of the RTK's high positioning accuracy and the fact that it is more compact than a laser scanner.