Paving the way with automated as-built reports

Concrete installation is not as easy as it seems. Before a single drop of concrete is poured, there is a lot of work to do. Regular as-built reports play an important role in making sure the work is done right the first time, and therefore costly and time-consuming rework is avoided.

Unfortunately, on a busy construction site, as-builts are often overlooked until the end of the project, when they are needed for legacy purposes. Monitoring and documenting a project is still a mostly tedious and manual task.

Now, rather than depending on time-consuming and expensive ground-based surveys and outdated plans, project teams can use a crane-camera based aerial mapping solution to access 2D and 3D as-built data automatically and daily.

Barnhill Contracting Company, a long-established construction company in North Carolina, USA, realized the benefits of Pix4D’s CraneCameras on a residential building project.

Located in downtown Wilmington, North Carolina (USA), one block from the Cape Fear River, Barnhill Contracting Company undertook the demolition of an existing two-story parking structure and the new construction of a twelve-story and a thirteen-story tower, including retail space and mixed-use, a parking deck, and residential apartments.

Project details

| Company | Barnhill Contracting Company |

| Location | Wilmington, North Carolina, USA |

| Project description | Building demolition and construction of residential condos |

| Project size | 470,000 square feet |

| Data capture and processing | Daily |

| Hardware | Pix4D CraneCamera |

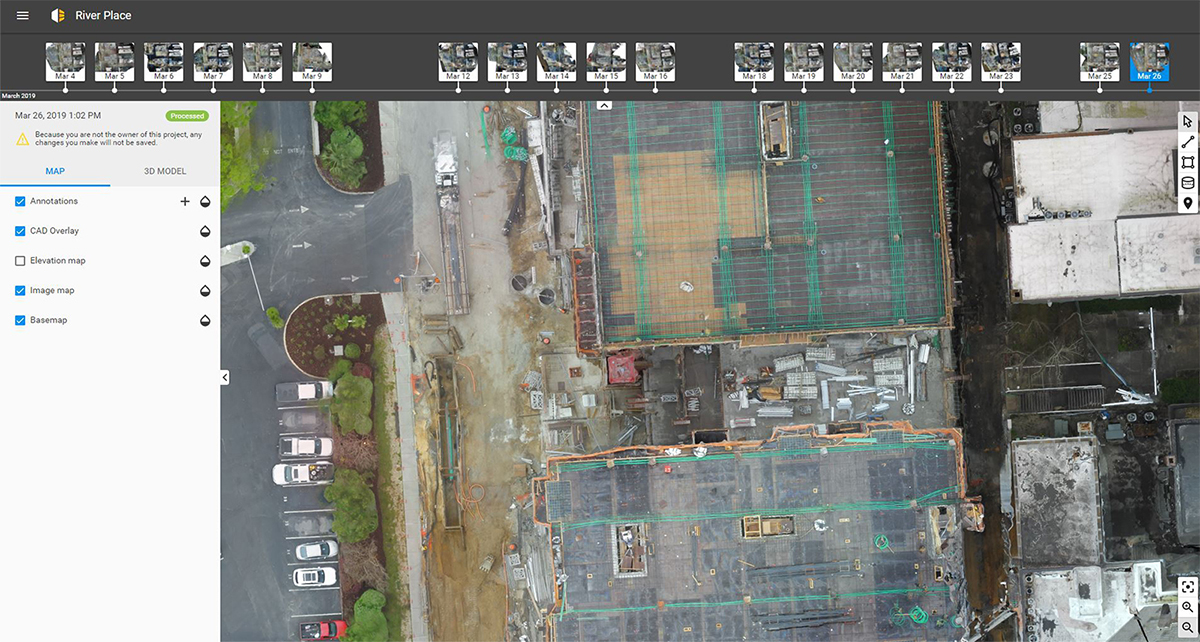

| Software | Former Pix4Dbim - Now Pix4Dcloud Advanced |

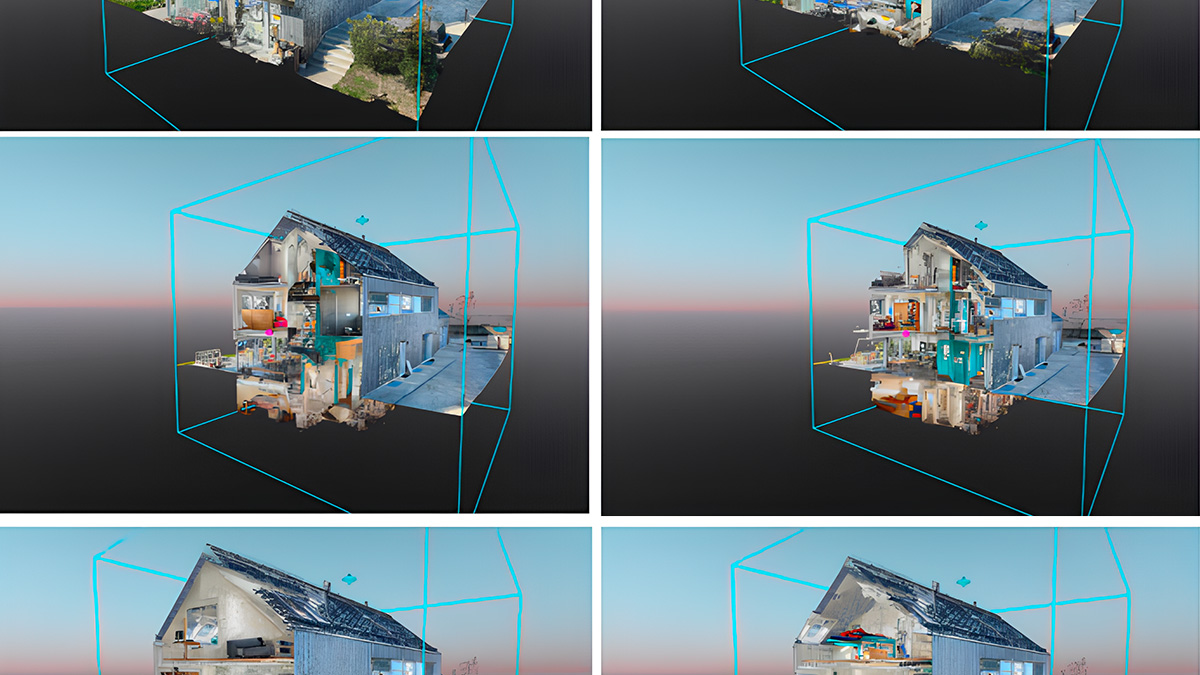

| Outputs | Georeferenced point clouds, orthomosaics, 3D mesh models |

Documenting is crucial

The cost of concrete work can quickly become significant. Over the years, techniques have been developed to lower costs.

One of the most popular is the use of post-tensioned concrete. In addition to strengthening the concrete slab and foundation, the post-tensioned technique permits the pouring of longer and thinner slabs of concrete. This can significantly reduce construction costs, saving material and labor expenses, and shortening construction schedules.

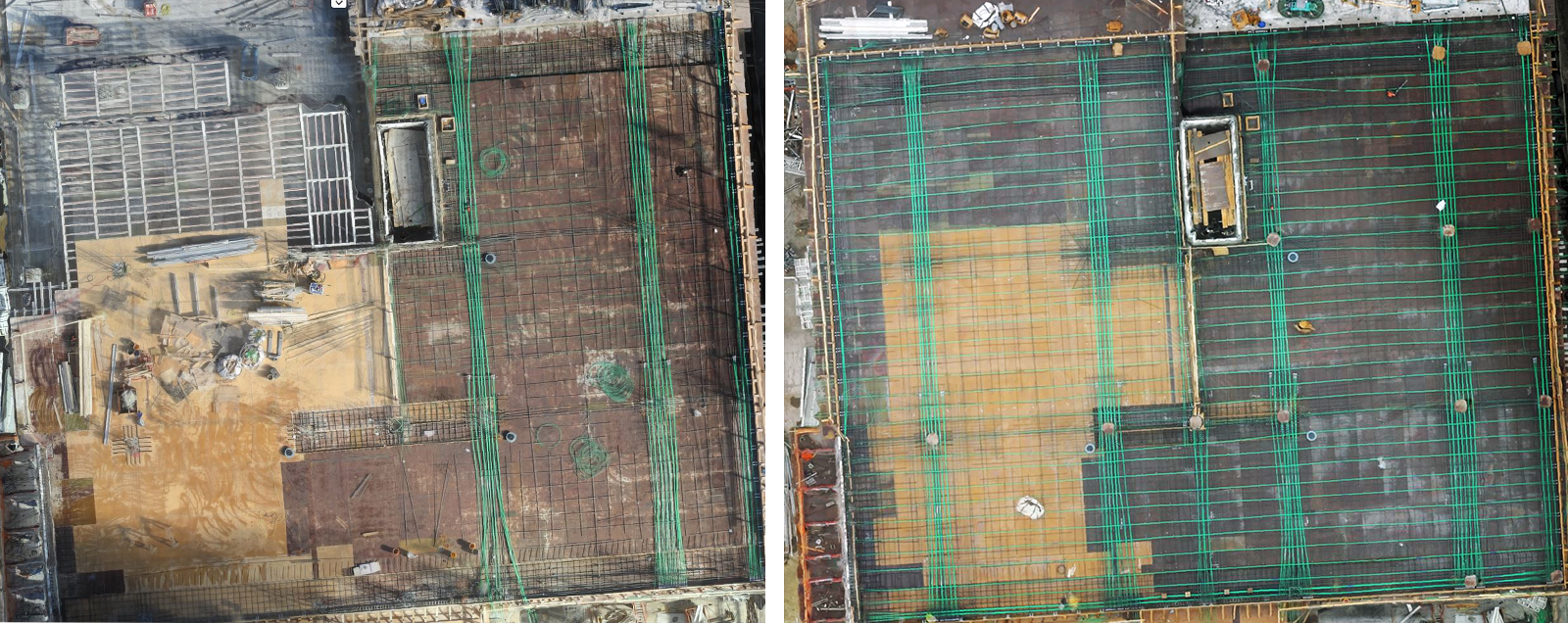

However, the actual laying of cables and pouring of concrete can sometimes be tricky. Since post-tensioned cables are tensioned after concrete is poured and post-tensioning places an active load on the structure, care must be taken during construction to make sure cable locations match engineering drawings precisely. Inaccurate cable places can greatly increase the uplift force on the slab and quickly cause costly rework.

Layton Lomax, Virtual Construction Manager at Barnhill Contracting Company explains: “We have a lot of post-tensioned concrete slab work on this jobsite. We really wanted a way to document the location of the post-tension cables and reinforced slabs. We needed complete as-built reports of all the structural components. That’s why we choose the CraneCamera.”

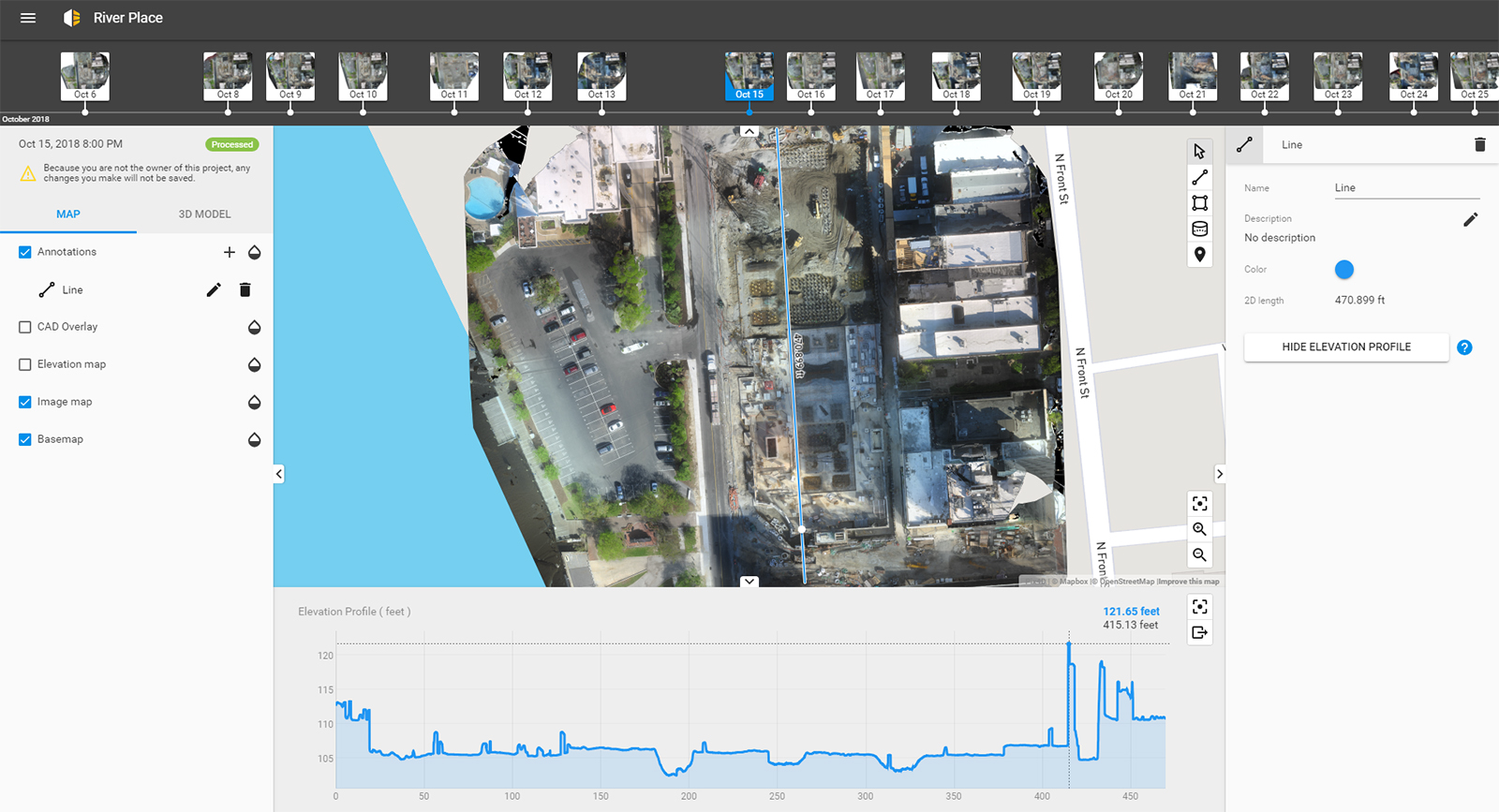

With the CraneCameras solution, all work on the site is monitored and documented daily, enabling Lomax and his team to verify the project is rendered as defined in the design phase and any errors or construction rework is avoided. “I’ve used the measuring tools to locate penetrations through the slabs and check on what's been installed in the field through the slab work. I was pretty impressed with the measuring tool that will give you an cross section view of the different elevations of what you're measuring. That's definitely useful.”

Mapping a permanent visual record

It’s not the first time the Barnhill team is turning to new technology to monitor job sites.

“In the past, we used drones quite a bit to scan post-tension projects”, comments Lomax. “But the challenge is to keep the drone around. When everything is ready to be scanned and the actual concrete pour will take place, it's difficult to break away and conduct a drone survey at the right time. The nice thing with the CraneCamera is that it's always there - I know that every day it captures the latest information.”

Because the CraneCamera solution is fully autonomous -- powered by the crane and working independently from the regular crane operations-- as well as fully automated, it eliminates the need for flight planning and human resources to be on site at the right time to capture images.

Once the camera systems installed, the team has been able to receive daily site updates without further intervention.

An essential in the construction toolkit

Every day new deliverables are available on PIX4Dcloud to be analyzed and shared with anyone who needs to review the current site status. “I look at the results every day, so does the team. This is something we would never be able to do with regular or even drone surveys. It’s a good way to track our progress and document the site. Every day, I send our higher-level management a link to the cloud and they're able to check what has been done - we're able to keep them up-to-date”.

The Barnhill team relies on the PIX4Dcloud platform during their daily meetings with the project subcontractors. “Most of the time, we use Pix4D on a big screen and point out the areas they need to work on or areas we can move equipment to - it's kind of a logistic tool for those meetings, definitely used daily!” explains Lomax.

At Barnhill Contracting Company, both managers and field operators were eager to try this crane-based system. “Our top management really wanted something like this from the start to document projects: getting daily documentation of what has been done and using it as an as-built for the post-tensioned slabs.” Lomax concluded: “The solution answered our expectations. It works very well. We have not been disappointed at all.”