How PIX4Dcloud Advanced boosts construction site management

Using traditional methods, the management of a construction site can be achieved through systems of communication through a common platform for knowledge distribution. Progress meetings are then used to forecast the schedule and budget during each period. The data for these meetings comes from weekly reports and production quantity calculations generated by field engineers. This process can be done manually, using hand-drawn sketches and calculations on notebooks, but the workflow is time consuming and slow. That’s why using drones to perform construction management is a faster, easier and safer way to capture essential and accurate data to manage and track production on construction sites.

Parsons (NYSE: PSN) is a leading disruptive technology firm working on global security, intelligence, and critical infrastructure. The company works not only in designing, building, and delivering infrastructure but also in enhancing it with smart, innovative technology solutions. Their innovative work spans from cyber defenses to improving on-site operations with better equipment.

Why the construction industry is adopting drones

As many in the construction industry know, measuring wheels are sometimes used in lieu of Computer Aided Design (CAD) software to calculate quantities for production on job-sites. Weirdly shaped objects often get a fair share of guestimations to calculate areas, especially for patchwork that is not shown on the plans. As is typical in the industry, the subcontractor, contractor, and owner’s representatives all measure the same location and record their quantities. This is usually based on each team’s availability to measure the site after work is completed.

As quantities are recorded, each person may record a few square feet of difference based on their respective methods for adding together irregular shapes. The difference in measurements is often magnified at the end of the month, resulting in large cost differences on the payment schedule and cashflow planning. To resolve this issue, re-measuring at the end of the month between the owner’s inspectors, the subcontractor, and the general contractor is often required. This could cost hours of unnecessary and tedious rework. Seeing this as a major inefficiency for the Parsons field engineers, the team turned to using drones for weekly flyovers to save time and get accurate site measurements. Having prior experience with Pix4D, the team chose to go with PIX4Dcloud Advanced for tracking quantities accurately and creating a single source of truth for the quantities.

Project details

| Location | Denver, Colorado |

| User | Parsons Construction |

| Software | PIX4Dcloud Advanced |

| Hardware | Phantom 4 Pro V2 |

| Images collected | 500 per site |

| Processing time | 1 hour |

| Output | GeoTIFF |

Drone mapping for tracking construction site progress

Creating a single source of truth helped Parsons to both track quantities accurately and resolve disputes over produced quantities, but also ensured they could accurately predict upcoming material requirements, update the budget, and accurately track progress.

Field engineers on-site made sure that everything was being built and billed correctly, checking the drawings, reviewing the specifications, and working closely with sub-contractors. The responsibilities and concerns change from site to site, depending on whether they need to monitor stockpile changes or identify underground utilities.

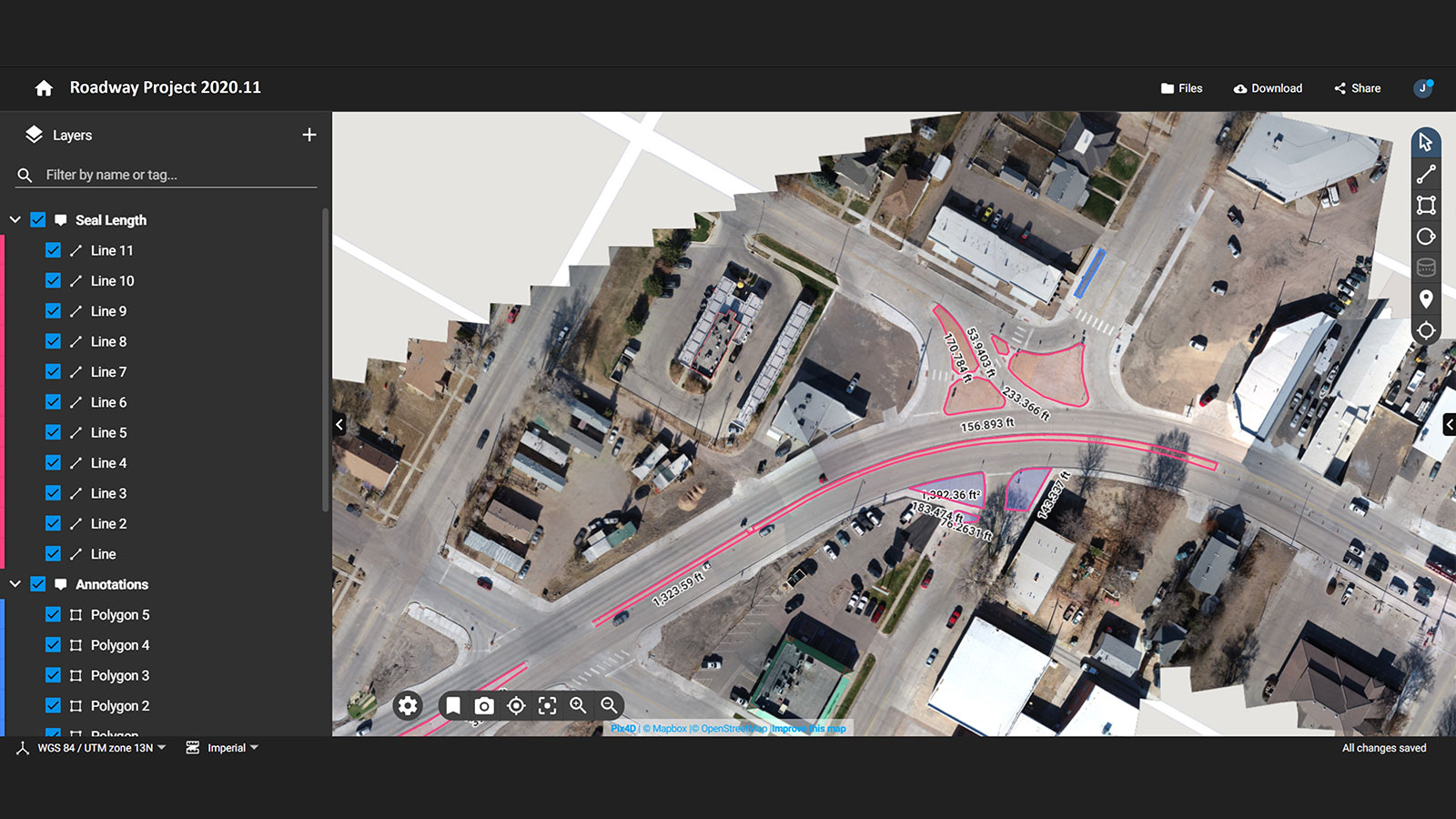

On this roadway project, production quantities of the same material, such as concrete, were measured in various forms to include different types of curb ramps, gutter types, sidewalks, driveways, and roadways. Each line item had a different unit price and sometimes even had different methods of measurement, depending on how or where it was installed. By tracking the items using Pix4D’s software tools, each type of concrete placement could be discerned accurately. It was easy to get behind tracking when the weekly production was very efficient, so drones helped the field engineers to not only remember exactly when and where work was done, but also accurately capture the quantities.

The team even found ways to use the drone data that was not originally anticipated. They used the images to locate water shutoff valves, locations of recently placed sewer pipes, and identify the location of utilities that were marked by spray paint on concrete that was subsequently removed. Whenever there was an issue, the drone imagery would naturally be used as a method for quickly resolving the dispute.

Due to the proximity of the project to active roadways and heavy construction equipment, Parsons used visual observers to ensure the safety of the flight operations. All field engineers and multiple members of the crews were trained to become visual observers and assist in flight operations. One of the field engineers served as the drone pilot after completing regulatory certifications and passing the Parsons drone program training. The project was large and very linear so automating a flight pattern and ensuring adherence to regulations was all the responsibility of the pilot with oversight from the company’s Drone Operations Team. Once photos were captured, they were uploaded to PIX4Dcloud Advanced for processing.

2D aerial maps for construction

Processing was done in the field office with an internet connection. This saved the pilot from having to carry around a powerful laptop as PIX4Dcloud is run entirely online and sends notifications to the pilot when processing is complete.

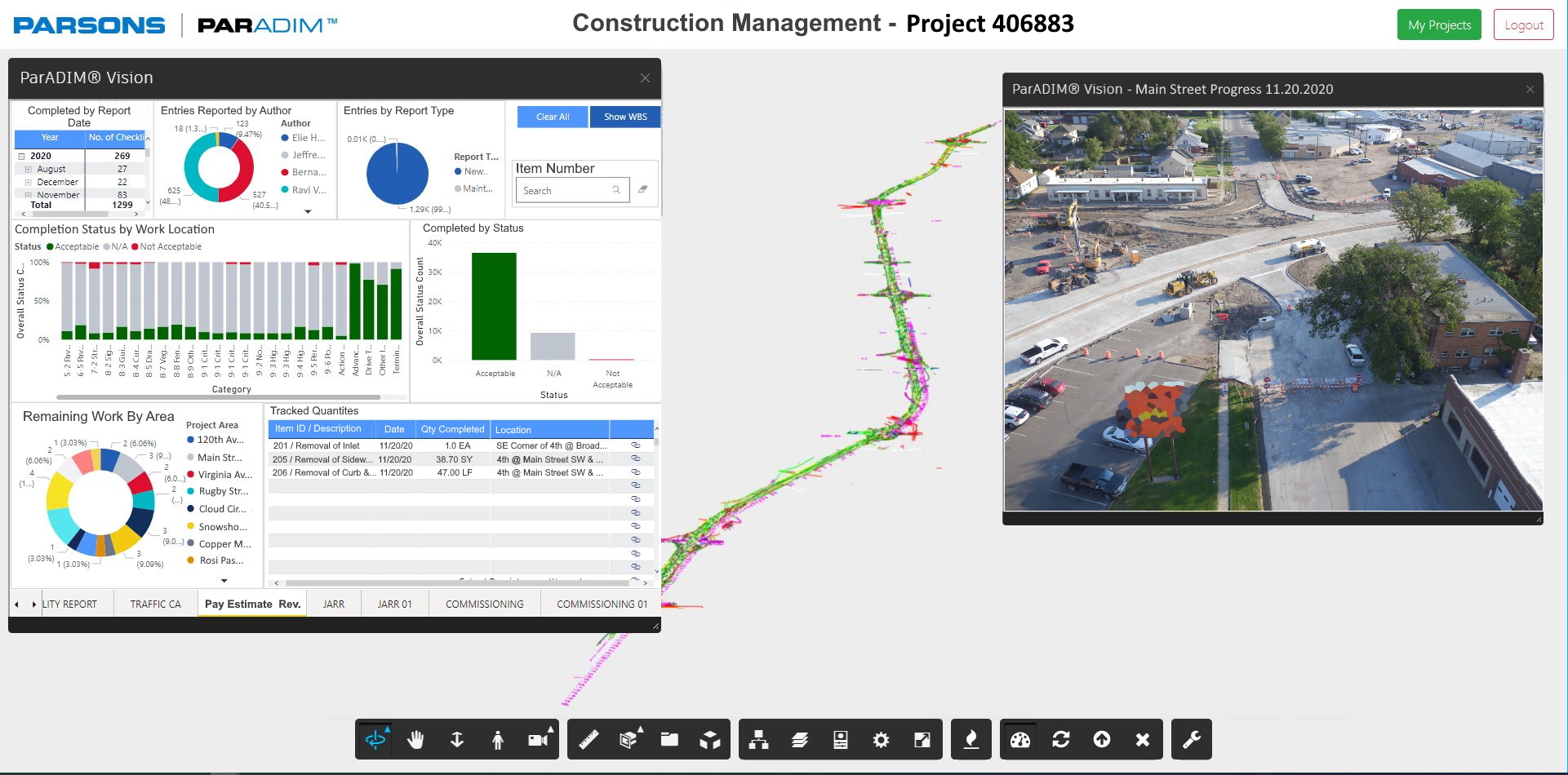

Parsons engineers then used the 2D orthomosaics to measure distances, analyze stockpile shapes, and count items. They added annotations about the data the orthomosaic showed, the responsible subcontractor, and other pertinent notes including the locations of important features like locations of water shut-off valves and other buried utilities. The extracted information was then entered into their digital twin solution - Paradim®, which then linked the entered data to other project information to extract insights and create a dashboard about the project metrics.

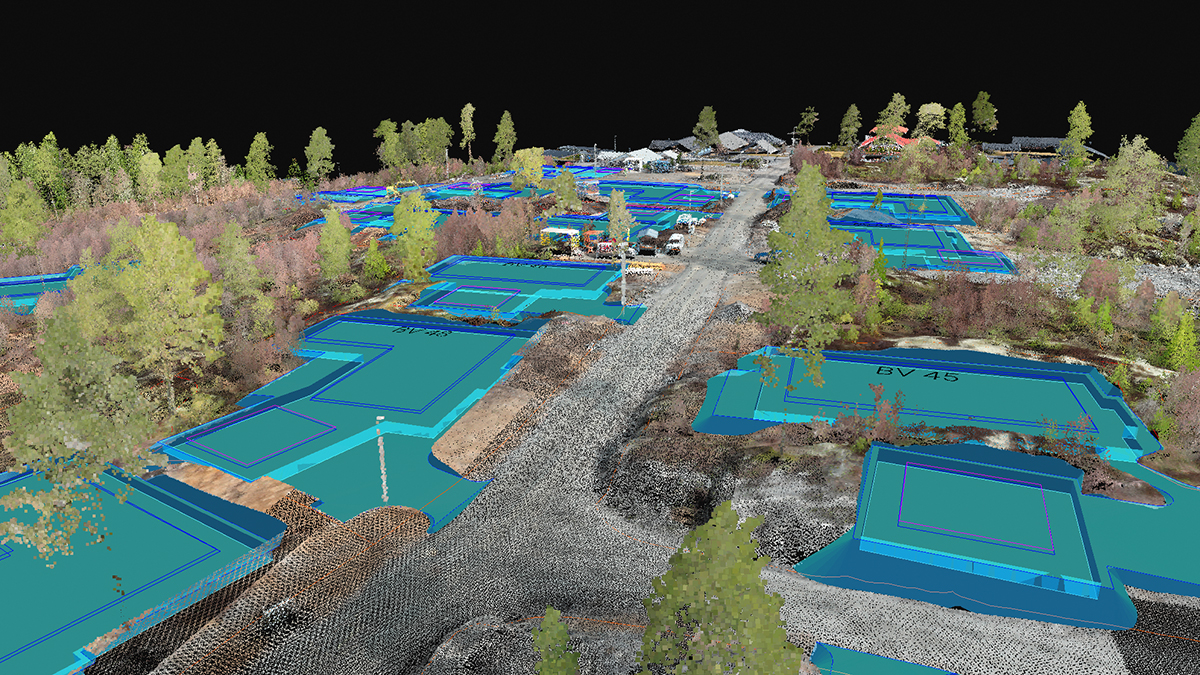

Although they primarily used the 2D orthomosaic for the management of this project, they found it useful to have 3D models of the site that could be compared over time on the Timeline feature of PIX4Dcloud Advanced to look at stockpiles and estimate usage of materials. Other features, such as the overlay feature, were immensely useful for tracking or comparing as-built with as-designed. Parsons has seen advantages of this across multiple sites and uses both the 2D and 3D photogrammetry outputs to improve site operations.

The benefits of using drones in construction

Thanks to drones and photogrammetry, Parsons can save time and money on-site by identifying problems early on, tracking progress, and avoiding rework. Drones are one tool in the bigger picture of digitizing the construction site. BIM models and other technologies are deployed in parallel with drone technology to maximize the effectiveness of the technological suite.

“Parsons has utilized Pix4D since 2016 for a variety of projects ranging from geophysics and environmental work to engineering design and construction site management. We are excited along with the drone community about this particular Pix4D use case as it highlights drone technology in the larger digital infrastructure landscape.” - Jeffrey Hong, Construction Drone Lead

PIX4Dcloud Advanced is specifically designed to assist in site progress tracking and management in construction. The ability to have project online, on a shareable platform has made a huge difference to constructors worldwide. Better communication and site awareness saves time and money without affecting operations on-site. It also saves unnecessary site visits by stakeholders thanks to having accurate 3D models of the features on sites that are constantly updated. Parsons is seeing continued success as a result of effectively implementing technology on their construction sites.