Inspecting one of the biggest industrial sites with drones

The collaboration between FURAY and VEIKI-VNL originally started as a test project where VEIKI-VNL provided the site and FURAY had the opportunity to scan various objects. The goal was to test the capabilities of PIX4Dinspect and to see if VEIKI-VNL could use the results. Once the first scans were completed and VEIKI-VNL saw the promising results, the project’s goals and extent were changed.

Using PIX4Dinspect for industrial site inspection

| Location: | Budapest, Hungary, at VEIKI-VNL Kft. industrial site |

| Companies: | VEIKI-VNL FURAY Photogrammetry Solutions |

| Hardware: | DJI Mavic Air 2 / DJI MAvic Mini and Air 2 / Pentax K-S1 |

| Software: | Pix4Dinspect |

| Number of inspections: | 3 |

| Image resolution: | 12 megapixels |

| Processing time: | 3 inspections processed parallel in 2 hours |

- A much safer inspection process - no accidents

- Inspection possible without turning off the electricity

- No need to rent out inspection equipment like cranes

- Inspection time reduced from one week to one morning

The project took place in Budapest, Hungary, at the VEIKI-VNL Kft. industrial site. VEIKI-VNL is part of the DEKRA Group, and the company is doing high electricity testing on its site, testing different insulations and electric machinery. The Hungarian site chosen for the test is one of the biggest in Europe. The scope of the project included scanning and inspecting three different objects.

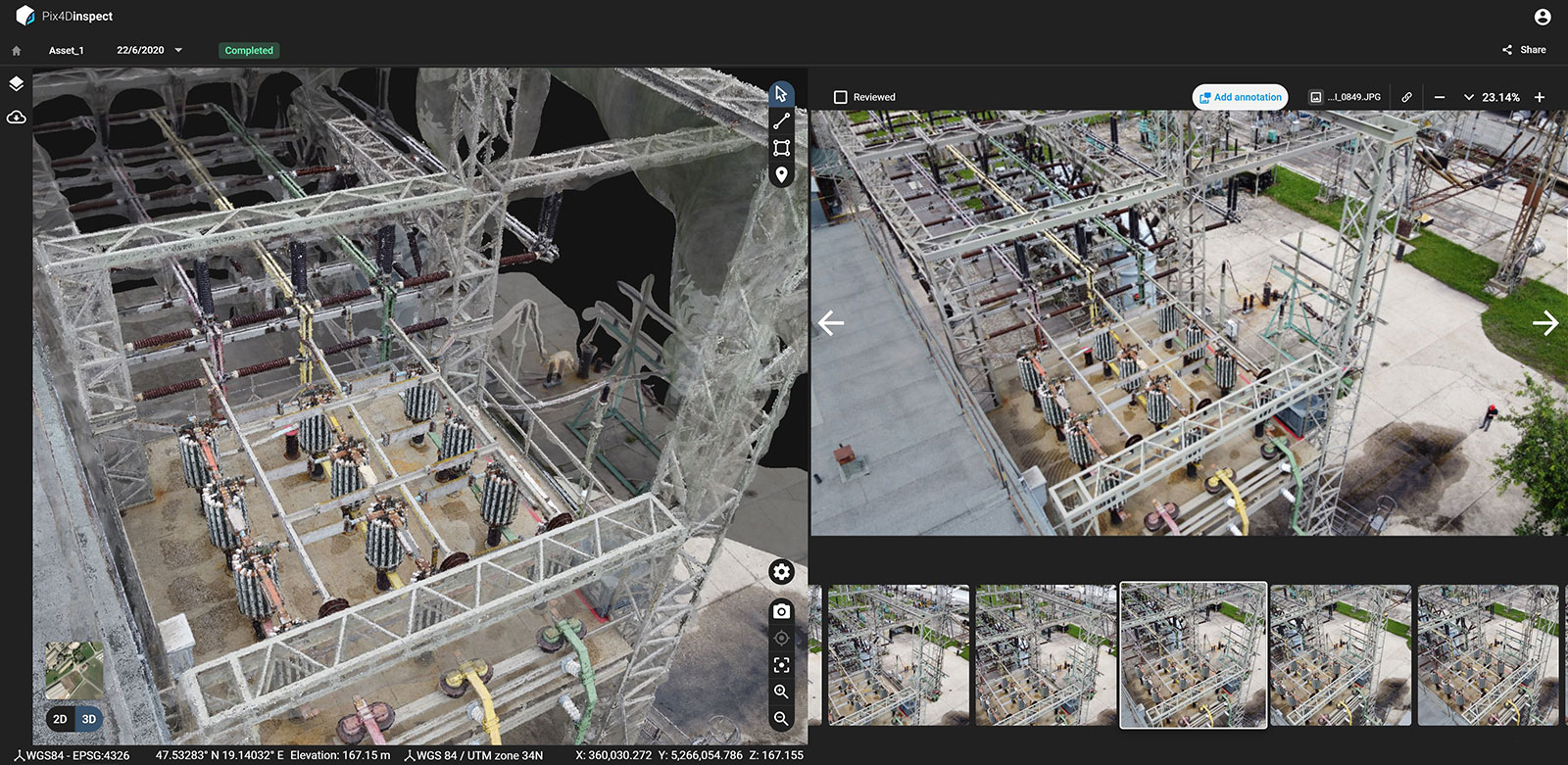

Creating a 3D model of an INDELVE transformer

First, VEIKI-VNL needed a 3D model of their small power INDELVE transformer. Because the inspection was done using a drone and PIX4Dinspect inspection software, there was no need to cut the electricity for operations, which resulted in cost savings. Additionally, the scan took 30 minutes to complete and data processing took around two hours, making the data collection workflow faster and more precise.

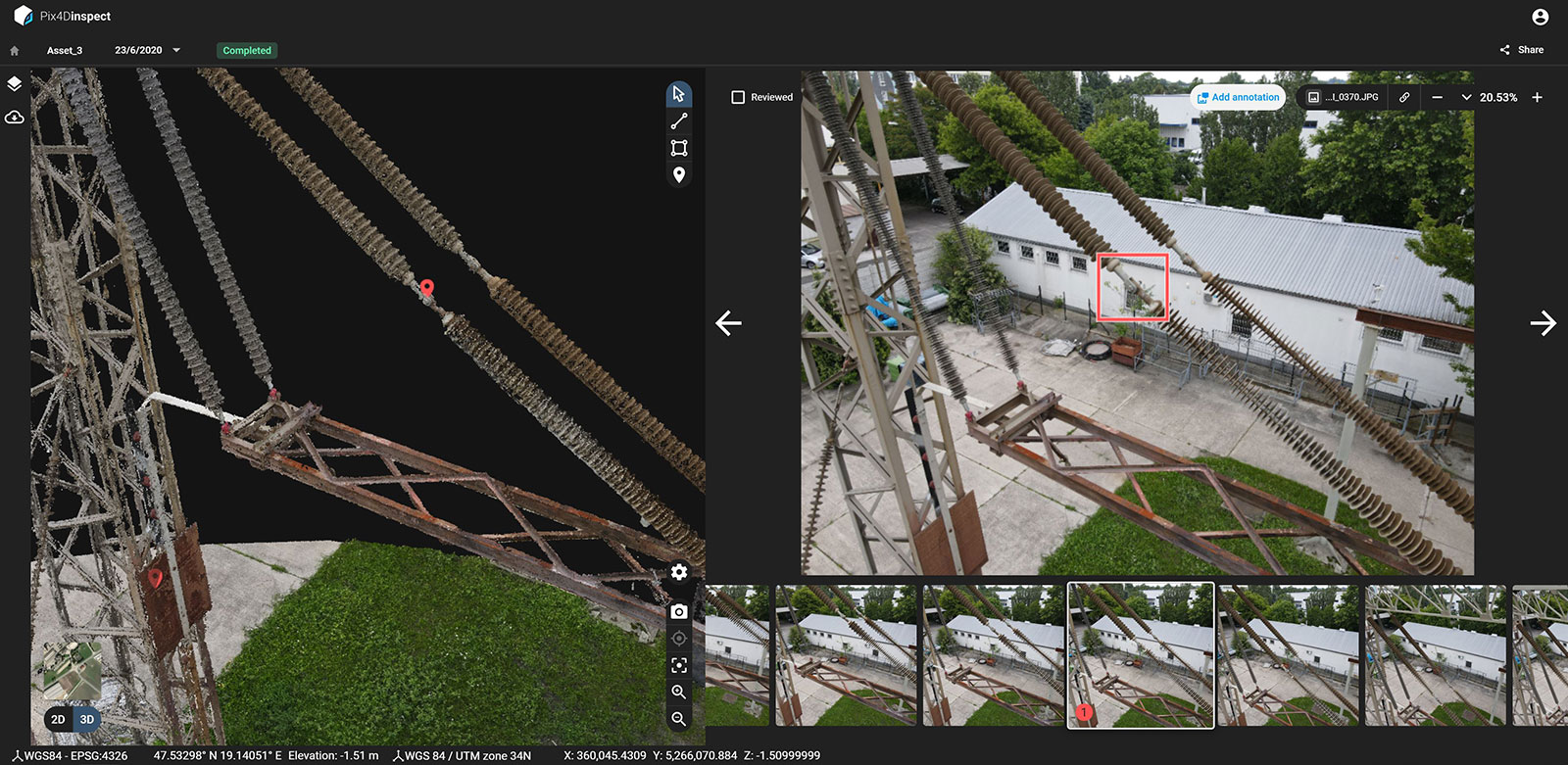

Inspecting pylons and voltage controllers

The second task was to inspect a pylon to check its structural integrity. Pylons are one of VEIKI-VNL’s oldest structures and they support high-voltage insulation. Therefore, surveying the structural integrity of these supporting structures is critical. By using drones there was no need to rent equipment, like platforms or cranes. Additionally, manually inspecting the structures would have been time-consuming and dangerous for inspectors because they could easily fall from the structure.

The drone scan and software processing were executed in under two hours, after which the results were analyzed on the PIX4Dinspect platform. Several issues were uncovered and ranked by severity as shown in the PDF report example below.

Finally, the third task was to inspect the VEIKI-VNL voltage controllers located on the roof structure. The voltage controllers can easily be accessed on foot and closely inspected without drones. However, both companies were interested in inspecting the controllers without shutting them down, saving time and money, which resulted in Jenő flying the drone. The scan did not uncover any significant problems apart from some corrosion and surface treatment issues.

When comparing the time spent on a project like this with traditional manual methods from before, it took VEIKI-VNL an entire week to do the inspection. By using drone scanning, PIX4Dinspect processing speed and inspection tools, they achieved more accurate, faster and safer results during a single morning of inspection.

Flying the DJI Mavic Air 2 and Mini to map the industrial site

“Although there was a jungle of cables surrounding the structures on site, I managed to acquire the data without any issues,” says Jenő Barta, Founder of FURAY Photogrammetry Solutions.

Jenő flew a combination of the DJI drones to get the data and, overall, both Jenő and the inspector were very satisfied with the speed and the quality of results they achieved with PIX4Dinspect.

“Pix4Dinspect was a straight-up choice because it made the inspection process way faster. Instead of checking all the photos we collected, we can now only inspect the specific ones we need, from every angle we need and save a lot of time,” points out Jenő.

Advantages of using Pix4Dinspect

Jenő Barta, Founder, FURAY Photogrammetry Solutions

Jenő and the inspector point out some of the software advantages that helped them to achieve the project’s goals:

- The image uploading and cloud processing are quick.

- The results are detailed and accurate.

- Pix4Dinspect provides a smooth user experience where navigation and inspecting structures are straightforward.

- The data processing, generation of the 3D model, and analysis were all executed with Pix4Dinspect. Additional third-party software was not needed.

- Exporting results was convenient and easy. An inspection report for the client could be generated in one click with all the inspected sites and corresponding annotations, which is a considerable improvement compared to having to create it manually.

Watch our inspection webinar!

Join an online session to discover how digital twins can help perform your inspections faster and better than before.

Watch now“By using a drone data collection made the entire process way safer, faster, and uncovered issues that couldn’t have been found by the eye on-site,” says Jenő. “Pix4Dinspect’s functions made the entire workflow very simple, easy, fast to inspect the structures, and export the results,” concludes Jenő.

A special thank you to Jenő Barta for sharing his story with us. The project report is available as a pdf: FURAY Photogrammetry Solutions