$100,000 saved: using PIX4Dcloud Advanced in construction

A large scale construction site can have thousands of moving parts, from machinery to workers to teams of trade contractors, all alongside raw materials being brought in and used. All sites must prioritize safety and site records in order to ensure the crews are safe and to prevent costly rework.

W.E. O’Neil Construction, based in Chicago, works on different construction sites ranging from office and retail buildings to large-scale residential projects. They use drones together with PIX4Dcloud Advanced across their operations to help visualize projects and to track site progress. The Pix4D software can be used for anything from stockpile measurements and tracking to documenting sites and comparing as-built versus as-designed.

The benefits of drones in construction

W.E. O’Neil recently completed work on One Oak Brook Commons, a 17-story upscale apartment complex in Oak Brook, Illinois. They wanted to bring drones to the site and use PIX4Dcloud Advanced to avoid rework on concrete decks by identifying mistakes early. The structural design called for post tensioned concrete slabs. This type of concrete is reinforced with steel cabling that is tensioned after the concrete deck is placed. Because of the tensioned cable, if a sleeve is missed, rework requires GPR (ground penetrating radar) or X-ray scanning of the deck (a time-consuming and expensive task) to locate the cables before re-work is completed. It also requires accurate coordination of deck penetrations prior to placement of the deck to ensure the size, quantity, and locations of the penetrations are correct. Missing a sleeve can cost over $2,000 to re-work per sleeve. There is a clear need to have as-built records of the sleeves throughout the build to avoid missing any and prevent expensive rework.

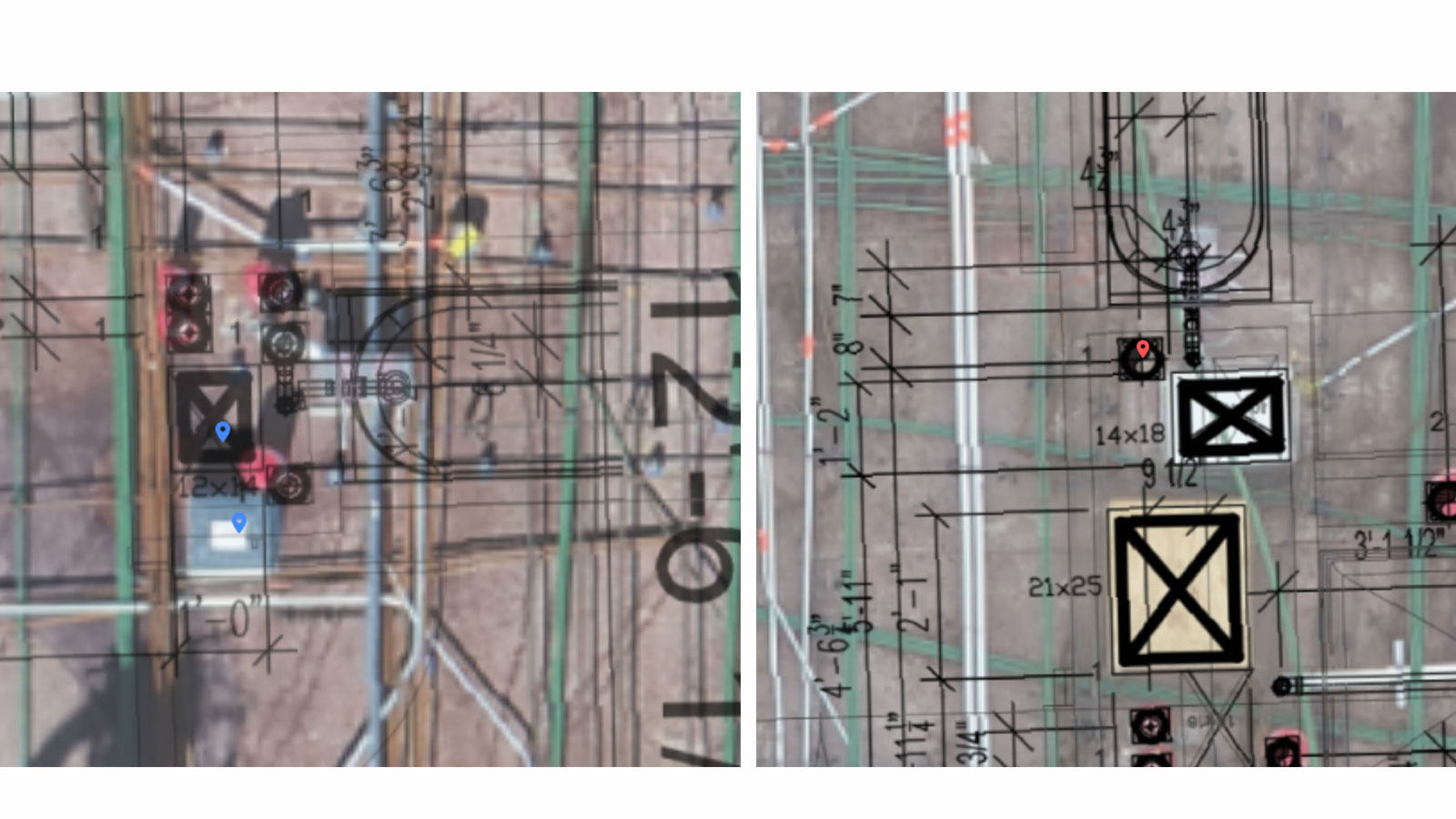

W.E. O’Neil wanted to use Pix4D's cloud platform to create maps of the deck of each story to ensure the coordinated penetrations had been done correctly compared to site plans and drawings. These could be overlaid on PIX4Dcloud Advanced to check everything was moving according to the plan.

At first, the Project Manager was cautious about bringing a new workflow to the site, as they had tried a similar workflow with laser scanners and seen poor results. The W.E. O’Neil Virtual Design and Construction (VDC) Team was given 12 hours to prove their workflow could get the results they claimed were possible.

Project details:

| Location | Chicago, USA |

| User | W.E. O'Neil Construction |

| Software | PIX4Dcloud Advanced |

| Hardware | Phantom 4 Pro V2 |

| Area surveyed | 325,000 square feet |

| Images captured per flight | 40 - 120 |

| Flight height | 30 - 40 feet |

Return on investment of drones in construction

Drone pilot and senior VDC Engineer Chad Ramsey went to the site early in the day to get started. He flew his Phantom 4 Pro around the site while carefully avoiding data capture of any workers on-site to avoid distortion in processing. The flight took just 15 minutes to gather all the necessary data. Processing on PIX4Dcloud Advanced was done automatically within an hour, and Chad received an email notification that processing was complete. He had the 3D model and the orthomosaic map ready with the design plans overlaid on the captured images and ready for the Project Manager to review in about an hour. The entire process of capturing and reviewing took less than two hours from start to finish. Thanks to the success of the demonstration of this, and how it had a clear return on investment for using drones on a construction site and the VDC team received the green light to work on the multi-story building.

Preventing expensive rework with as-built updates

This construction site had an aggressive schedule that meant work had to move quickly. One level was placed every week that consisted of two separate pours. PIX4Dcloud Advanced was used to map and document levels 5 to 17 in just 2 months. A drone pilot on-site would capture data and upload it for processing. After processing was completed, the pilot would check the outputs were ready and add any overlays required by the Project Manager.

Over the course of 2 months, W. E. O'Neil identified roughly 48 missing sleeves prior to deck placement. Because these sleeves were found early on, no rework was required which saved time and money on-site.

“Had the team not been using PIX4Dcloud Advanced, the construction site could have faced over $98,000 in rework costs. Now, our Project Manager insists that a flight is completed prior to every pour to ensure that no sleeves are missed”, explains Director of VDC Chad Holbrook.

Improving site awareness and team collaboration

The site awareness provided by drones and photogrammetry has transformed how W.E. O’Neil can communicate, manage, and collaborate on the sites they work on. Thanks to the PIX4Dcloud online platform they can easily share data with the whole project team so that everyone can visualize the status of the project right away. Their typical on-site capture takes 2 hours total from image collection to processing and sharing their data.

“We have been able to use Pix4D to pursue more work and win more jobs. The use of Pix4D is now a company standard and is used across our projects.” - Chad Holbrook, Director of VDC at W.E. O’Neil

As they have used PIX4Dcloud Advanced more, the team has become more familiar with the software and found different methods to get even better results. Going forward, they intend to use Ground Control Points to improve their accuracy as they have found they have variances of around 2 inches (5 cm) in some results. This will allow for greater precision for site measurements and enhance the current level of success for progress tracking and site management. Thanks to using drones and PIX4Dcloud Advanced, W.E. O’Neil saved time, money, and brought a whole new workflow to their construction sites that have convinced their colleagues that modern innovation in technology is the future of the industry.