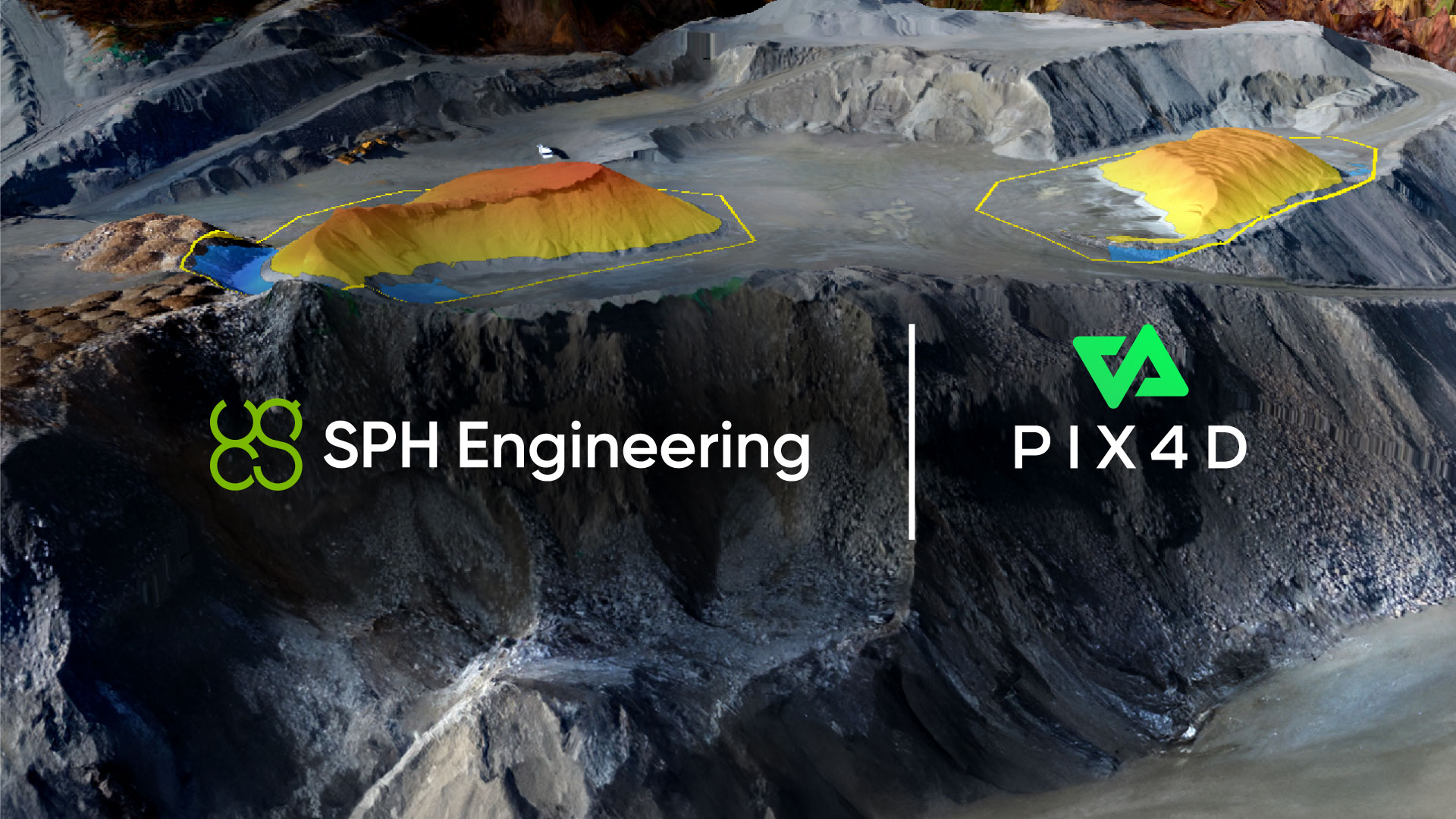

Stockpile management on a custom platform with PIX4Dengine

PIX4Dengine, our specialized photogrammetry platform that can be integrated into user platforms, has recently been adopted by Hitachi in order to assist in stockpile management as they oversee raw materials used in construction.

Hitachi, Ltd. provides the Hitachi Inventory Management System, which uses drones to efficiently manage vast raw material yards (yards) where iron ore and other raw materials are stored in piles. PIX4Dengine is running inside this system, supporting the Hitachi Inventory Management software with API-based 3D processing.

Streamlining Yard Inventory Management with 3D Data

In the raw material yard, the loading and unloading of coal and raw materials occur daily. In conventional inventory management, skilled workers estimated the volume of piles visually and generated a form, but since many piles are stored in a vast yard, it took a huge amount of work to measure each pile individually.

The Hitachi Inventory Management System provides a better system. By using a drone to photograph the material yards from the sky, and generate three-dimensional data of the piles from the image data in the cloud. The system automatically calculates the volume of the pile from the generated 3D data and automatically measures inventory information such as inventory volume, available space, and shape, thereby reducing the burden of manual labor and records, which is improving inventory management efficiency.

In this system, PIX4Dengine is used to generate three-dimensional models from image data. When an image of a pile captured with a drone is uploaded, PIX4Dengine's Cloud API is executed in an internal process to generate a DSM and orthomosaic from the image. Another system developed by Hitachi, Ltd. receives this data and goes through the process of automatically calculating volume, area, etc., and the aforementioned output is provided to the user through a web browser.

PIX4Dengine enables early commercialization

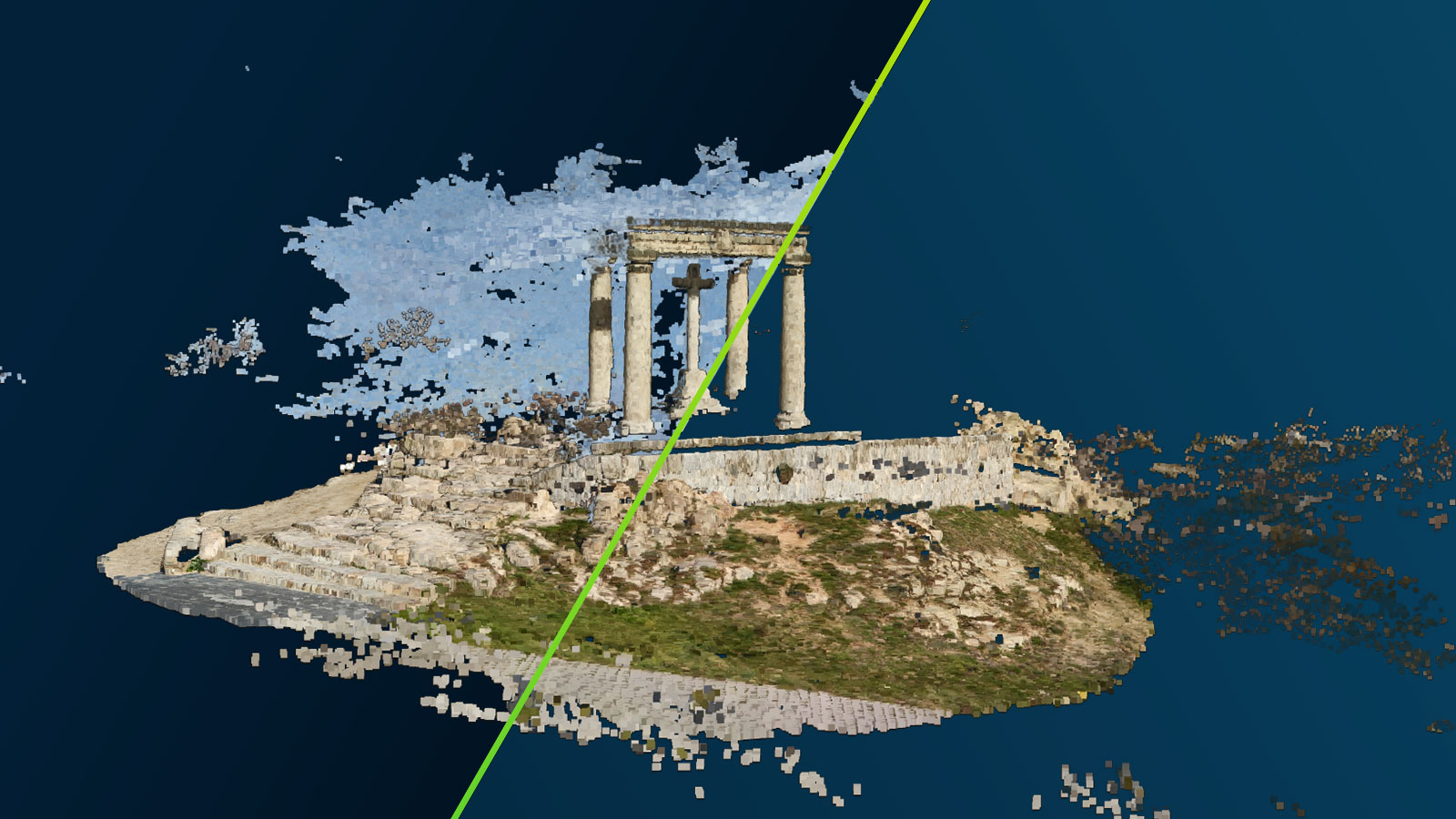

In developing this system, the ability to generate three-dimensional data to calculate raw material piles was essential. In addition, to develop a scalable business, it was necessary to run multiple end-user processes at the same time, so it was critical that the system operate online on the cloud. Therefore, when we started development, PIX4Dengine Cloud API, which was the only cloud API system with photogrammetry functionality, was introduced.

By using PIX4Dengine, we were able to easily incorporate 3D data generation technology, which is difficult and expensive to develop in-house, into our service and release the service in a short period of time.

Mr. Wakizaka of Hitachi, Ltd. said, "We were able to release our cloud service quickly by using PIX4Dengine (Cloud API). By leaving the photogrammetry (SfM) technology to PIX4Dengine (Cloud API), we are able to focus on higher value-added activities specific to our customers' business.

The Hitachi Inventory Management System is currently being tested at Company 0, and end users have commented that they are happy to be able to automatically create documents that were previously shared on paper and that the cloud system makes it easy to share with people in other departments.

As the need for digital transformation in business is increasing, PIX4Dengine will continue to support customers' systems so they can deliver new value to society using photogrammetric technology.