Measuring stockpiles on the point cloud: can it be faster?

Stockpiles have a place across multiple industries, from construction to mining. The process of accurately quantifying and monitoring stockpiles has always presented a challenge to site managers in terms of knowing the volumes, transporting quantities to the correct locations, and ordering new stock. Naturally, stockpile measurement and analysis is a widely required feature for photogrammetry software.

Currently, stockpile measurements are possible with PIX4Dcloud, PIX4Dmapper, and PIX4Dsurvey. The current workflow for PIX4Dsurvey involves a user creating a polygon in the point cloud around the stockpile, which is called the stockpile toe. The volume of this is then automatically calculated by the software. However, annotating the outline of this toe can be tedious and time consuming. Our goal was to provide users with a faster way to outline stockpiles and simplify the process.

The information in this article was provided by Fayez Lahoud, Senior Data Scientist at Pix4D.

How we optimize a feature using algorithms

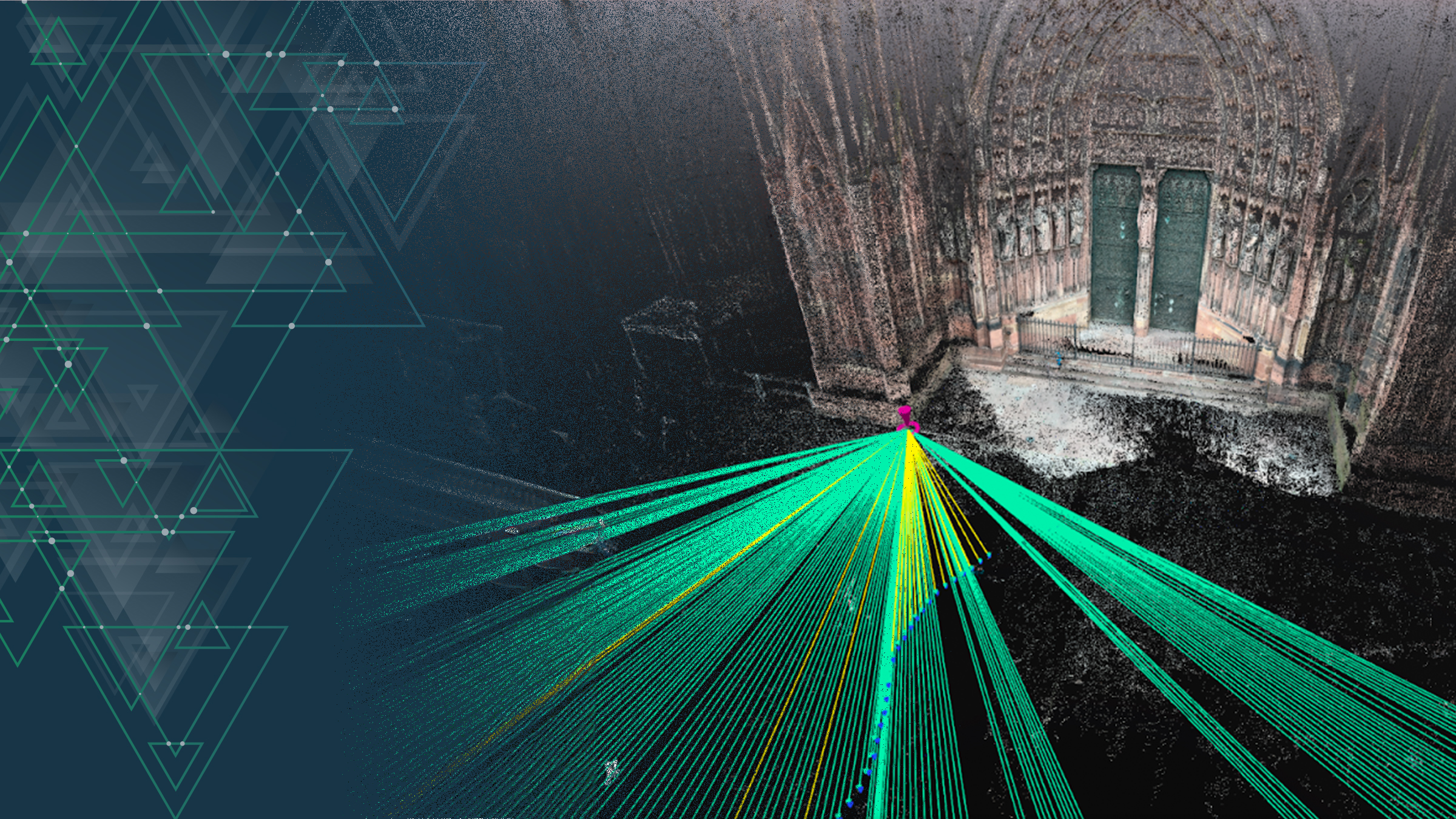

Our plan for this was to use a point cloud region growing algorithm to create an improved workflow.

An interactive region growing algorithm can assist users in defining the stockpile area with a single click. This algorithm is grown from an original “seed” pixel that is identified by the user. It will add nearby pixels that it defines as similar to the seed, which increases the number of points selected by the algorithm. With this method, the software can identify the points related to a stockpile with minimal input from a user - cutting time on creating a polygon for the stockpile toe.

Reflections on using a region growing algorithm

After we implemented the algorithm and tested it, we found that it was able to reliably identify stockpile toes in the majority of cases. The algorithm is deterministic, meaning it will produce the same outputs every time. It relies on the seed point, a gradient threshold (slope), and a color threshold (LAB chrominance).

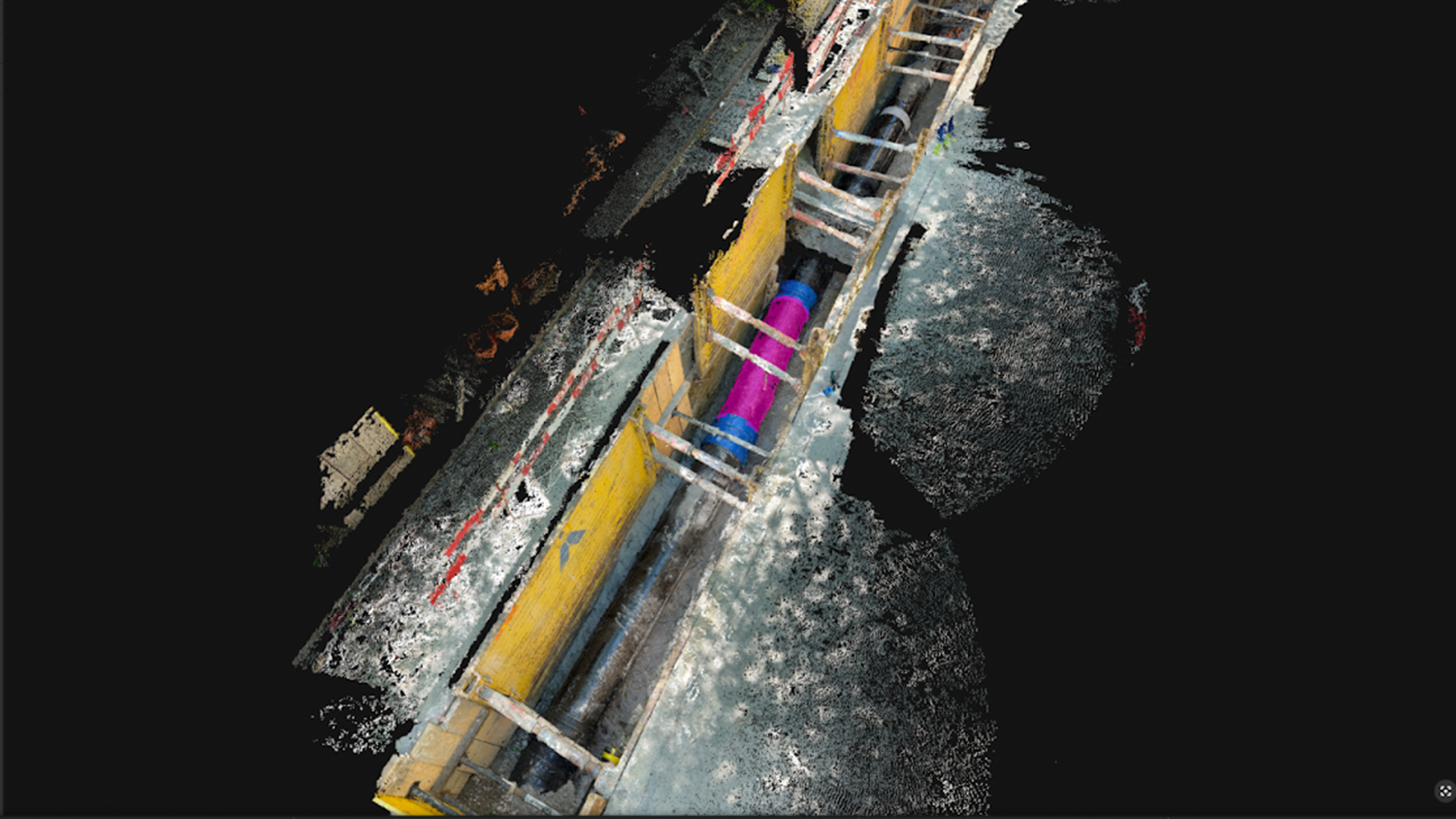

For example, these yellow polygons above were automatically extracted from single seed points. Using the slider, you can see how the automatic extraction has identified the stockpile area without a stockpile toe being drawn.

After our testing, we found that the majority of the stockpiles could be automatically identified with the default parameters. Some editing was occasionally required to fine-tune the gradient and color thresholds in order to better delineate the exact outlines of the stockpiles - or their toes.

We also found that using color filters based on LAB chrominance (which perceives light and color the way people do, looking at both lightness in addition to color) helped the algorithm to differentiate stockpiles that could be next to each other and made of different materials. This is an important point for us as it can help our clients avoid confusion and set our products apart.

What comes next?

Assisted stockpile detection is now a part of our software running on PIX4Dsurvey. The Precision of Volume was 98% for the majority of stockpiles, and 91% for stockpiles toes that are located on sloped terrains. This level of precision provides a faster workflow that is part of measuring volumes. The results can be used by constructors, surveyors, and site managers.

Our findings have helped us automate a system that was initially a time-consuming task that is faced across multiple industries. Our automated volume measurement feature is already live on PIX4Dsurvey and we hope to add it to other products with time. The applications could also be completed with 3D models captured with PIX4Dcatch and the viDoc RTK rover, a terrestrial scanning device, as well as with aerial drone imagery or photos captured with construction tracking hardware. We have been able to save time through our R&D team developing a tailored algorithm for our software. Maybe, in the future, we can develop fully automated algorithms that remove the requirement for a user to click on a seed pixel.

Got questions, or want to get involved? Join the conversation on LinkedIn and follow our hashtag #Pix4DLabs!