Marti Construction verifies site with drones and Pix4D

When working on a project in Switzerland, international construction company Marti used a new construction verification solution from Pix4D. Marti operates in all major areas of construction, including structural and civil engineering, tunneling, and road construction.

While building in Lausanne, they combined daily drone flights for data capture with Pix4D software for creation and visualization of mapping results on a web-based software platform..

Data acquisition and processing

The workflow is automatic and therefore repeatable on a daily basis, something that would be difficult and expensive to achieve if multiple manual processing steps had to be followed.

- Pix4Dcapture defines flight path and serves as autopilot for flight and image capture.

- Images are transmitted and processed in the cloud.

- Orthophotos are uploaded to Pix4D web platform.

Data-driven analysis and decision making

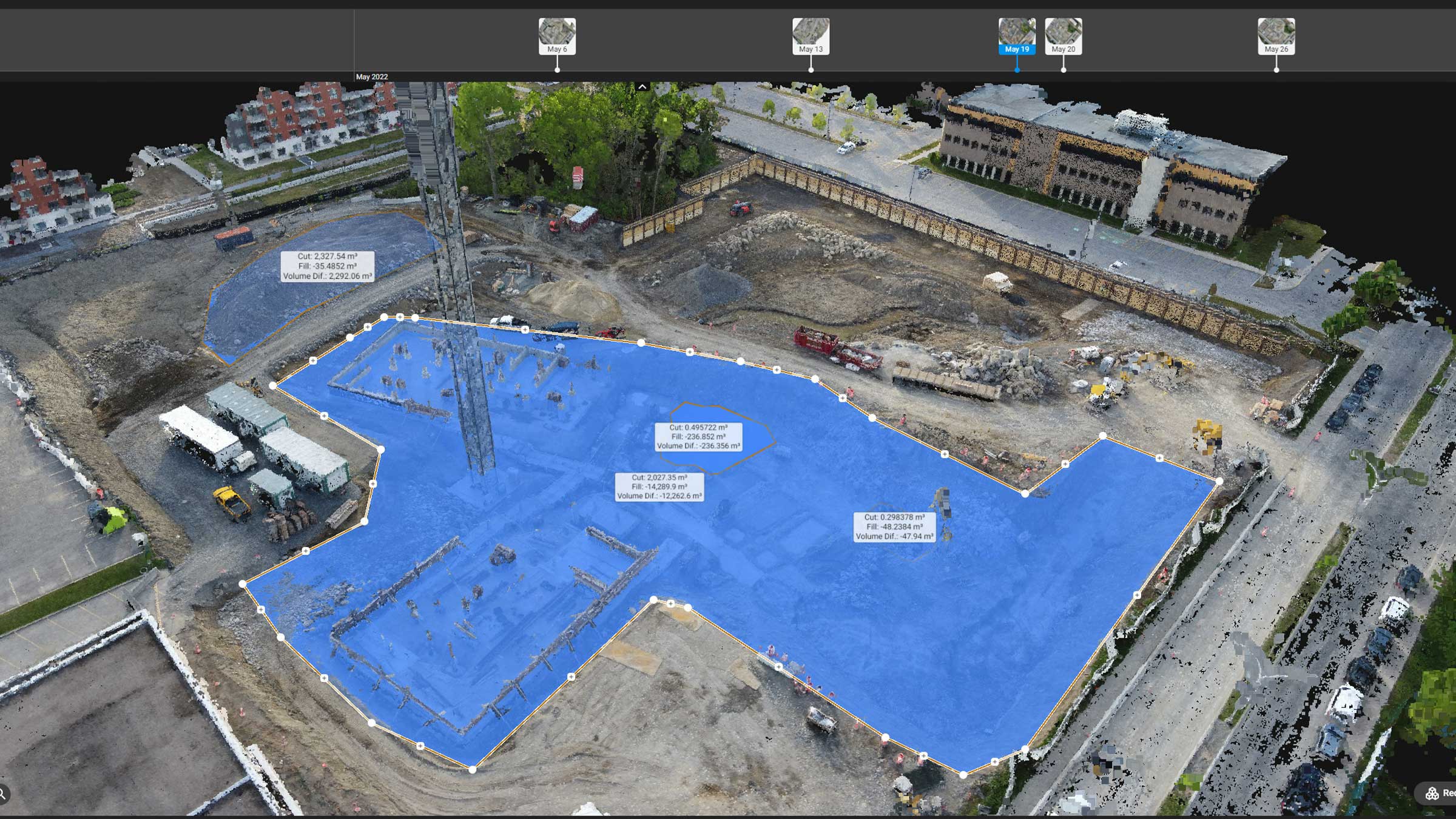

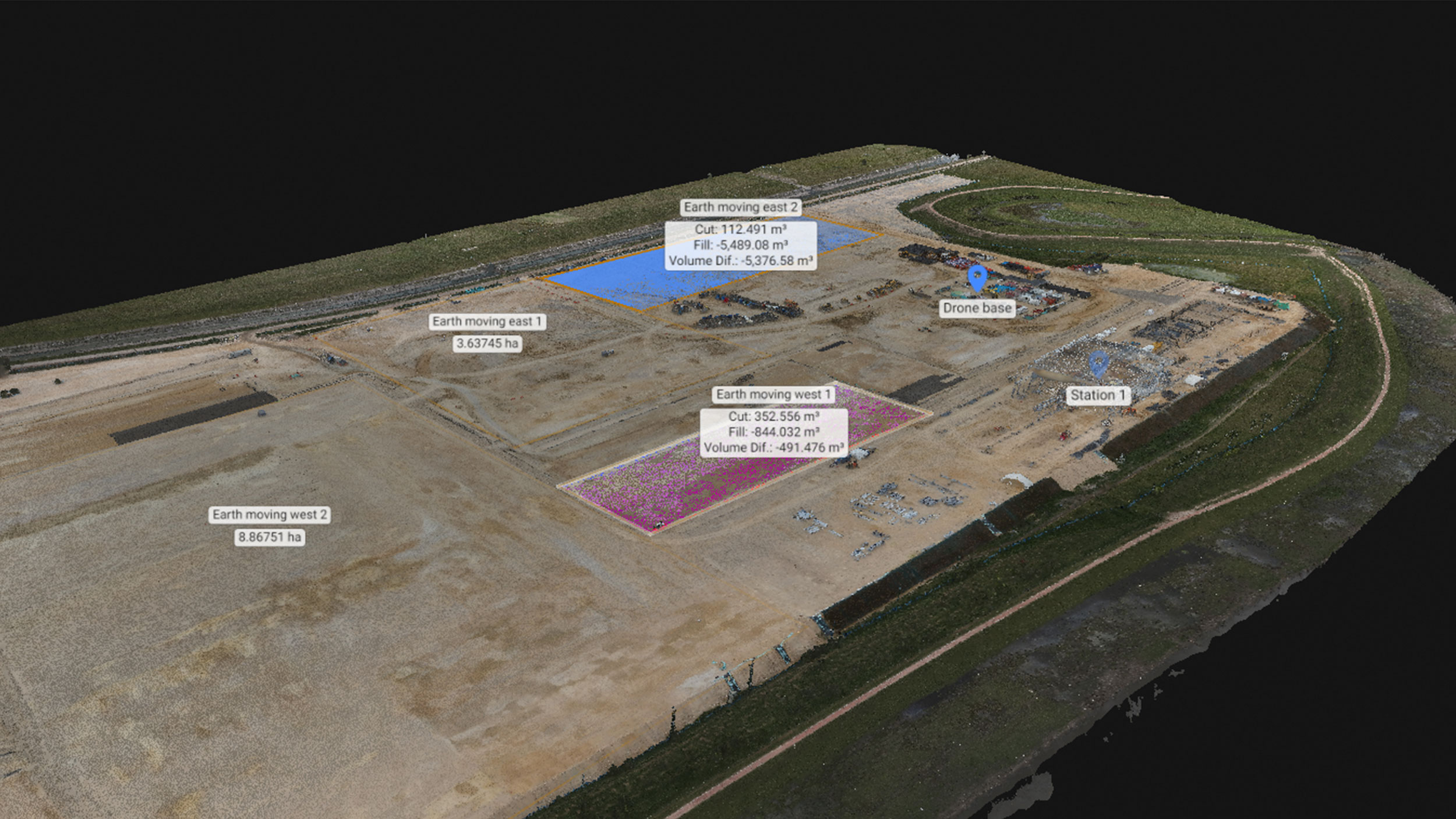

After the orthoimage has been produced and uploaded to the Pix4D web platform, it is viewable by anyone with an account and internet access, along with the 3D site model. Make distance and area measurements along with image annotations for comment sharing.

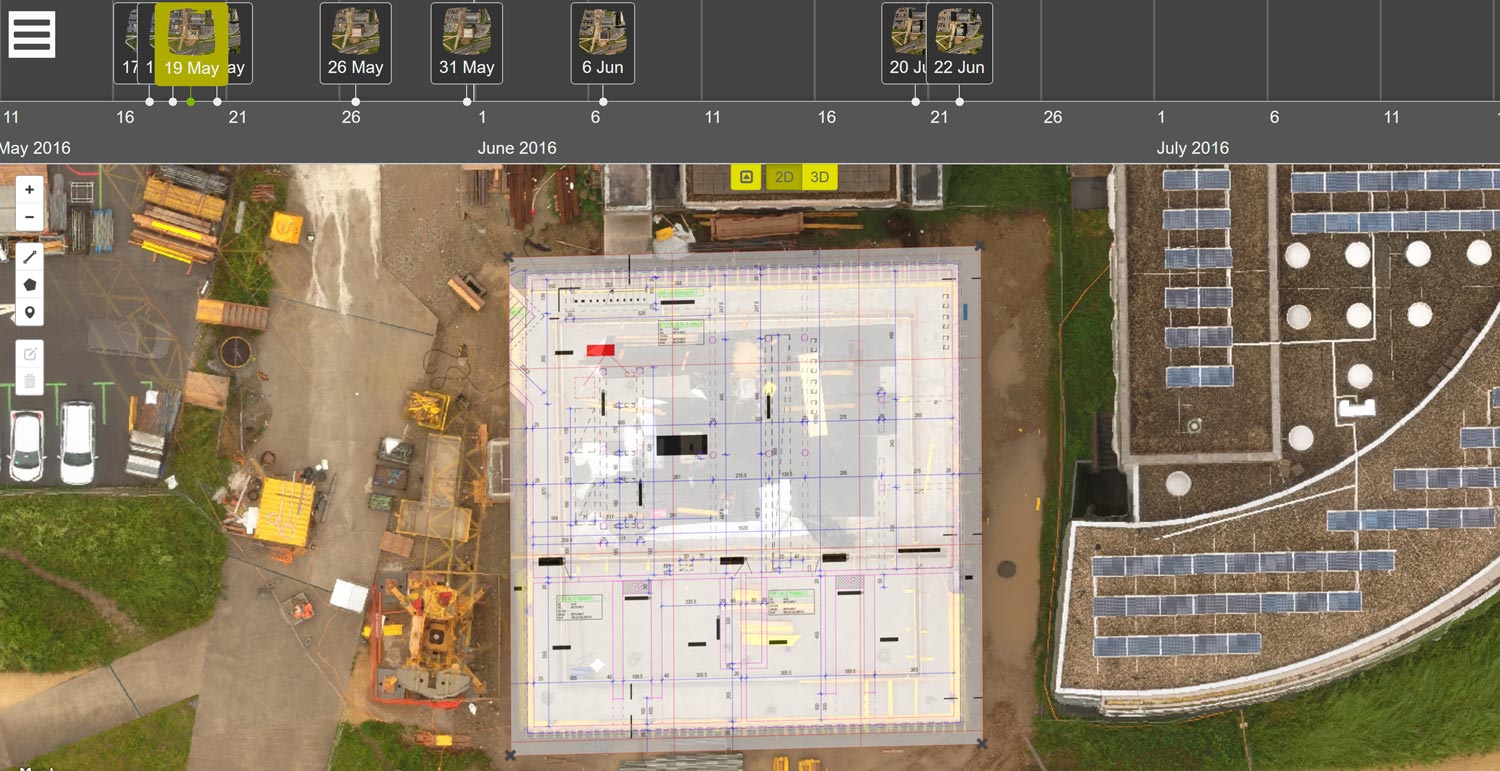

Orthophotos are displayed on a timeline and can be compared side-by-side for comparison over time.

Construction drawings, CAD or BIM design models can also be compared to orthophotos, enabling the site manager to check the as-built site status against the design.

Saving time and money, automatically.

Most large budget projects optimize construction by using the BIM process: a detailed construction schedule that must be closely adhered to if the project is to be completed both on time and on budget.

Any deviations from schedule must be identified as soon as possible for the BIM process to be corrected. By comparing scheduling drawings to as-built orthophotos, the BIM manager is able to have daily updates on site status, generated by an automatic workflow.